I have never made box joints. I always thought they were done on the table sawAlso, on this cherry case, as opposed to the oak ones in my earlier post, I offset dado cut the ends before cutting the box joints with jig. That way I was only cutting box joints through half the width of dimension lumber. My short router bit could not cut through 3/4" oak lumber in the other boxes I made without two passes. The box joint cuts were consequently not very clean. And the cherry lumber was actually 7/8" so definitely needed to do something else. The result was interesting in that the sides had classic box joint appearance while top and bottom show dado joints.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Woodworking Hunt Talkers?

- Thread starter hansontyrel

- Start date

OntarioHunter

Well-known member

- Joined

- Sep 11, 2020

- Messages

- 5,998

Get a router jig. It can be done on a table saw but very awkward if the piece is long like the sides of the gun case. Requires standing the board on end and keeping it vertical while pushing through the table against the fence. A long board wants to wobble. Hard to control. Also very tedious as only a blade width can be cut out for each pass.I have never made box joints. I always thought they were done on the table saw

TheBenHoyle

Well-known member

I was given marching orders a couple weeks ago that my daughter needed a lofted Fram for here bed. Since it is firearm deer season here in Illinois this weekend and I don't want to be anywhere near the woods, I spent the weekend making sawdust in the garage.

It turned out just the way she wanted and it was a lot of fun to have her helping. She really enjoyed it and I think I may have made her into a lifelong woodworker.

It turned out just the way she wanted and it was a lot of fun to have her helping. She really enjoyed it and I think I may have made her into a lifelong woodworker.

BrentD

Well-known member

Mission accomplished. Nice work.

mdunc8

Well-known member

What are those?Turned these into a nice little side hustleView attachment 165347

mdunc8

Well-known member

Fly boxesWhat are those?

slatebuilder

Well-known member

- Joined

- Jan 27, 2018

- Messages

- 654

It’s not a fine wood working project per say, but it is a wood project, and one that is cool pretty cool. One of the science teachers at the school I teach at is a big water fowl hunter. He approached me about building some nesting boxes as a co-teaching project between science and tech.ed.

Sounds good to me.

The tech ed kids laid the ground work making jigs, fixtures, CNC programs and a plan of procedures. It took them about 6-7 class periods to get everything ready for the science kids.

When the Science kids arrived they were able to manufacture 6 nesting boxes from rough sawn to completion in 80 minutes.

Sounds good to me.

The tech ed kids laid the ground work making jigs, fixtures, CNC programs and a plan of procedures. It took them about 6-7 class periods to get everything ready for the science kids.

When the Science kids arrived they were able to manufacture 6 nesting boxes from rough sawn to completion in 80 minutes.

Attachments

geetar

Well-known member

That church is gorgeous. I bet the acoustics are amazing. I’d love to strike a few chords on an old hymn in their.We've dabbled in timber frames and log homes.

Here's a small church... disclaimer: Only machined (tooled/notched) the timbers on our CNC machine.

View attachment 91375

View attachment 91376

View attachment 91377

View attachment 91379

And a log home:

View attachment 91380

View attachment 91382

View attachment 91385

View attachment 91386

nwihunter

Well-known member

BigHornRam

Well-known member

OntarioHunter

Well-known member

- Joined

- Sep 11, 2020

- Messages

- 5,998

Walnut or hickory?I'm not much of a woodworker. I just make things flat and let nature handle the rest.

View attachment 165949

R

rwc101

Guest

Walnut.Walnut or hickory?

I'm an amateur, but at times pretty ambitious. I absolutely love timber frame structures, so I figured I'd bring it to my backyard. My dad and I spent months reading and learning how the heck to make this thing... and here is the product.

We started out with hammer and chisel on the joinery... and then I ended up purchasing a chain mortiser (best money ever spent). I live in a pretty warm climate, but these crisp mornings sipping coffee underneath it make me reminisce about fall and all things deer and elk... just as God intended

We started out with hammer and chisel on the joinery... and then I ended up purchasing a chain mortiser (best money ever spent). I live in a pretty warm climate, but these crisp mornings sipping coffee underneath it make me reminisce about fall and all things deer and elk... just as God intended

Attachments

jjmatthew95

New member

- Joined

- Jan 13, 2021

- Messages

- 1

Damn, I wanted to tell you how to make all sorts of wood products and burn patterns on them, but here in the comments whole HOUSES made of wood. I feel inferior, as if I came to the gym for the first time among the jocks. Okay, so. I make different wood products and burn cool patterns on them. I started doing this when a friend of mine recommended Toolschief to me to keep me busy with something in my spare time, now I make custom products and earn a little money on it. The guy above is just a $*)Q!#@$ gazebo! I envy you kindly, honestly, ha ha. I wonder - what kind of tree is this? It looks really very nice to look at , all these natural patterns on the wood, damn, very cool!

Last edited:

TheBenHoyle

Well-known member

Don't be shy. All woodworkers matter.Damn, I wanted to tell you how to make all sorts of wood products and burn patterns on them, but here in the comments whole HOUSES made of wood. I feel inferior, as if I came to the gym for the first time among the jocks.

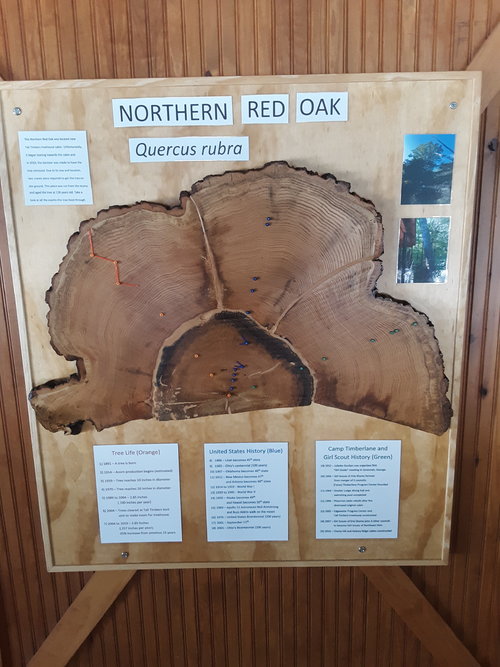

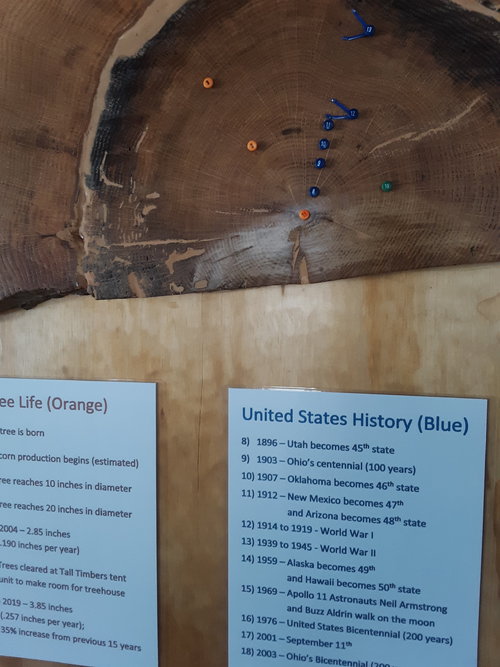

A little bit of an unusual woodworking project. The campground I work at had a big red oak that started leaning towards a cabin and had to be cut down. I cut a cookie of the butt and mounted it so the growth rings could be seen. I labeled when a few important events took place throughout the tree's 128 year life. Sometimes I get desperate to put my forestry degree to use.

Similar threads

Latest posts

-

-

-

Help Me Legalize Semiauto Rifle Big Game Hunting In Pennsylvania

- Latest: roger1shot

-