Addicting

Well-known member

Or the kids I need to avoid….You've got the patience of an oyster.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Or the kids I need to avoid….You've got the patience of an oyster.

Amen. I need a shop. It's all ready in my mind just need to break out the benjis.Or the kids I need to avoid….

It’s nice, if you can squeeze it in you won’t regret it.Amen. I need a shop. It's all ready in my mind just need to break out the benjis.

Soon enough. 3 years maybeIt’s nice, if you can squeeze it in you won’t regret it.

Careful don't jinx yourself lol.I have one but rarely use it to work on anything.I drive Fords!

Yeah. Seems like I only use the shop when I'm doing brakes. Oil changes are outside. Half the crap on a vehicle now you can't hardly work on anymore!Careful don't jinx yourself lol.

Hell any more it's cheaper to take it somewhere half the time.Yeah. Seems like I only use the shop when I'm doing brakes. Oil changes are outside. Half the crap on a vehicle now you can't hardly work on anymore!

Perhaps if you lift it there would be enough room for the exhaust to be routed above the driveshaft. I think if it were under the driveshaft it's just asking for trouble.Been really hot this week and not much progress has been made. I’ve been plugging away at the exhaust. Got it to where it has to go under the rear driveshaft. I opted for that crossing verses under the transmission oil pan. I want to keep the extra heat out of the transmission. The drive shaft is 1.5” short since I changed to a shorter transmission.

Now I’m at a crossroads, to lift or not to lift that is the question.

I don’t want the extra height but I would like to get the front pinion lower and further from the header. Tuff country offers a 4” and that is as small as I can go to move the pinion down. All the leveling kits leave it in place and don’t help with the issue.

Here is a done one with a 4”. Looks pretty nice but it will be another 2k into this build.

View attachment 330606

It is flush with the bottom of frame cross member under the tail shaft of the transfer case. I left it where I could skid plate the frame and have a flat bottom.Perhaps if you lift it there would be enough room for the exhaust to be routed above the driveshaft. I think if it were under the driveshaft it's just asking for trouble.

I had an '85 Suburban although it was a 1500 with a straight front axle but until I put a 4" lift on it would drag the tail regularly going through washes and whatnot.

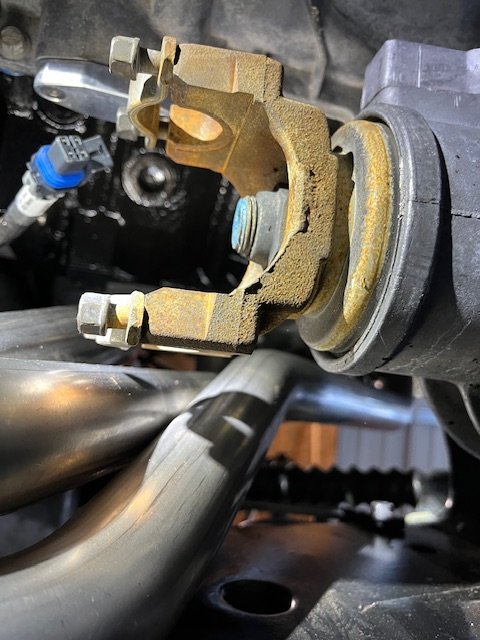

If you go back and look at the exhaust pics you can see how close the joint is to the header. I would say there is about 3/4” to 1” clearance. I am going to try and cut a heat shield but with it that tight I’m not sure how much it will do without rattling or catching on the yoke.I'll wait for the pictures but I can't imagine running the exhaust under a driveshaft. There is a little bit of movement there up and down and it could interfere. I would do everything I could to keep it as high as possible. Aftermarket heat shielding may help any concern of heat transfer.

Perhaps if you lift it there would be enough room for the exhaust to be routed above the driveshaft. I think if it were under the driveshaft it's just asking for trouble.

I had an '85 Suburban although it was a 1500 with a straight front axle but until I put a 4" lift on it would drag the tail regularly going through washes and whatnot.

I'll wait for the pictures but I can't imagine running the exhaust under a driveshaft. There is a little bit of movement there up and down and it could interfere. I would do everything I could to keep it as high as possible. Aftermarket heat shielding may help any concern of heat transfer.