Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon fiber Model 70 build

- Thread starter p_ham

- Start date

EKYHunter

Well-known member

- Joined

- Dec 13, 2020

- Messages

- 1,345

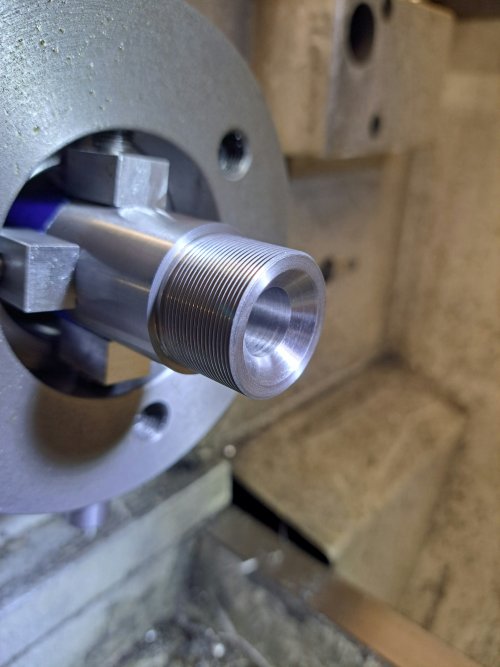

Nice!!!I'm behind schedule but I got the barrel tenon threaded, bolt nose cone cut, and chambered.

Muzzle high side was indexed at 12 o'clock.

Pre drilled and bored the chamber

View attachment 262973

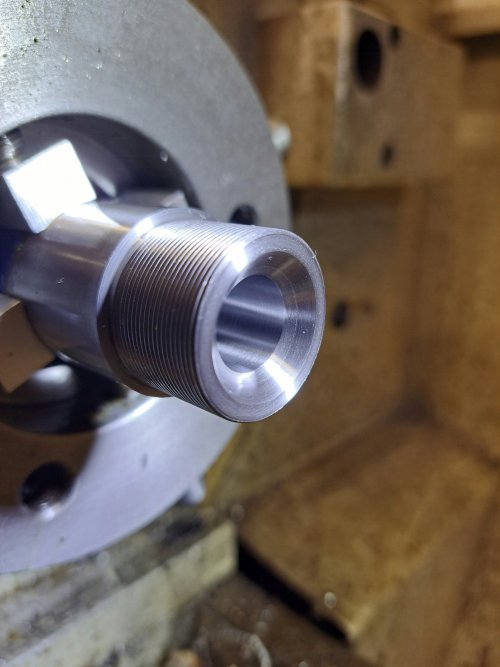

Chamber cut and polished

View attachment 262974

millerkiller77

Well-known member

I was curious about that also@p_ham

I gotta ask.

How do you index the high side at 12 without actually screwing it into the receiver?

Indexed high when hand tight, or did you take torquing into account?

Curious minds wanna know! Lol

std7mag

Well-known member

I mean i've indexed spark plugs on race cars before.

And sometimes that would be a PITA.

And sometimes that would be a PITA.

p_ham

Well-known member

@p_ham

I gotta ask.

How do you index the high side at 12 without actually screwing it into the receiver?

Indexed high when hand tight, or did you take torquing into account?

Curious minds wanna know! Lol

You do screw the receiver on. After the threads are cut, indicate the muzzle and mark the high side (at the tenon shoulder). Cut the shoulder back until you're a couple degrees from TDC. You can also index at 6 o'clock if that's closest.

Same basic process for timing a muzzle brake.

std7mag

Well-known member

Well, with all the lathe pics, thought i'd share what happened at work today.

Guy running the Haas ST35 had put a piece of 4140 shaft in to machine. 6" diameter X 4" thick slab off of a shaft.

We were all standing around talking, doing our shift turn over.

Suddenly BANG, BOOM, BOOM BANG!!

Piece is out of the jaws, laying on the chip conveyor.

Seems he forgot to put the 1.75" drill in and it tried to drill with the 1.25" boring bar.

Of course for those that don't know, the closer to the center of a piece your working, the faster the lathe spins.

Just glad it wasn't me!

Guy running the Haas ST35 had put a piece of 4140 shaft in to machine. 6" diameter X 4" thick slab off of a shaft.

We were all standing around talking, doing our shift turn over.

Suddenly BANG, BOOM, BOOM BANG!!

Piece is out of the jaws, laying on the chip conveyor.

Seems he forgot to put the 1.75" drill in and it tried to drill with the 1.25" boring bar.

Of course for those that don't know, the closer to the center of a piece your working, the faster the lathe spins.

Just glad it wasn't me!

p_ham

Well-known member

I worked in a shop machining raw carbide for a while. It's not solid, it's powder and a wax mixture that are super compressed. Lots of come-aparts in that place.Well, with all the lathe pics, thought i'd share what happened at work today.

Guy running the Haas ST35 had put a piece of 4140 shaft in to machine. 6" diameter X 4" thick slab off of a shaft.

We were all standing around talking, doing our shift turn over.

Suddenly BANG, BOOM, BOOM BANG!!

Piece is out of the jaws, laying on the chip conveyor.

Seems he forgot to put the 1.75" drill in and it tried to drill with the 1.25" boring bar.

Of course for those that don't know, the closer to the center of a piece your working, the faster the lathe spins.

Just glad it wasn't me!

jeff_gibbons

Well-known member

So cool!

millerkiller77

Well-known member

I use a lot of carbide tipped tooling and can say that 20-30% of it is freaking sketchy. Kennametal used to be the industry leader and innovators in carbide tipped tooling, now it's hard to differentiate between what's real and counterfeit. China has flooded the global market with counterfeit tooling...... and it's impossible to differentiate until you put it down the hole.I worked in a shop machining raw carbide for a while. It's not solid, it's powder and a wax mixture that are super compressed. Lots of come-aparts in that place.

Last edited:

millerkiller77

Well-known member

I'd love to know the answer to this also.What was your customer's goal for this rebuild request?

p_ham

Well-known member

Weiners on the cheek pad?I'd love to know the answer to this also.

p_ham

Well-known member

High end lightweight CRF 3 pos safety in 300WSMWhat was your customer's goal for this rebuild request?

millerkiller77

Well-known member

C&B on a jeweled bolt is freaking awesome and scientifically proven to produce .128 groups with factory ammo.Weiners on the cheek pad?

Weiners on the cheek pad is iffy, I guess it would depend on which way they are "headed"

I'm an ignoramus, had to look up what you were referring to in your last two answers.High end lightweight CRF 3 pos safety in 300WSM

p_ham

Well-known member

Tips to lips. That way with every shot you get a quick "peck"C&B on a jeweled bolt is freaking awesome and scientifically proven to produce .128 groups with factory ammo.

Weiners on the cheek pad is iffy, I guess it would depend on which way they are "headed"

millerkiller77

Well-known member

I can't stop laughing at that one. Post reportedTips to lips. That way with every shot you get a quick "peck"

Meanwhile you put the special order in for them though didn’t you!I can't stop laughing at that one. Post reported

millerkiller77

Well-known member

Gay for the stayMeanwhile you put the special order in for them though didn’t you!

Similar threads

- Replies

- 5

- Views

- 1K