Redmt

Well-known member

You got me thinking about a bunch of black walnut I've been milling and am in the overkill building of a router sled. How smooth a cut are you getting?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You got me thinking about a bunch of black walnut I've been milling and am in the overkill building of a router sled. How smooth a cut are you getting?

Very nice, what are you using to seal it after turning?I'm pretty unskilled at a wood lathe, but I'm determined to learn to turn well enough to make popcorn bowls and beer mugs. So this is attempt #3, a silver maple block of very wet wood. So wet that steam is billowing out of it as I bore 2.125" pilot hole to start. It seemed a bit more dramatic than the pic shows, but yall can get the idea

Carving the inside is what i do not do well, but carving the outside is always a lot of fun.

View attachment 280362

I quit for tonight and have switched to using my first mug for now while the rain comes down.

View attachment 280363

I use food grade epoxy both inside and out. On the outside, I heat the wood as much as I dare, apply the epoxy for a while with more heat and then wipe off. The inside gets a thicker, glossy coat.Very nice, what are you using to seal it after turning?

Also I saw a cool thing where old timers would take green wood and bore a hole through the middle and then put a dried circle cut piece on one side and when the wet wood would dry it would create a perfect shrink seal on it.

I would go 5/4 or 8/4, as long and as wide as you can make it. Gives whomever is buying it the most flexibility with the material. Rough cut black walnut brings $7-8 a board foot around here.I have a butt load of black walnut. I'm going to start running it through the mill in the next few weeks. I'm not sure how much of it to cut or in what dimensions. Any suggestions as to what could be marketable?View attachment 280765View attachment 280766

Wanna trade?I'm clearly not the guy to ask. My maple reloading bench is raw.

View attachment 281187

Nope. Mine is 12 ft long and weighs a ton. Not sure how I can get it out when the time comes.Wanna trade?

I dont think so. I went and picked up another quart and it went on pretty nice . The first can had the consistency of warm molasses, the second can was much thinner and spread much easier. First can was probably old stock that had been on the shelf for too long.Is it leaching up contamination from the old surface?

Too thick of application.I need some opinions here.

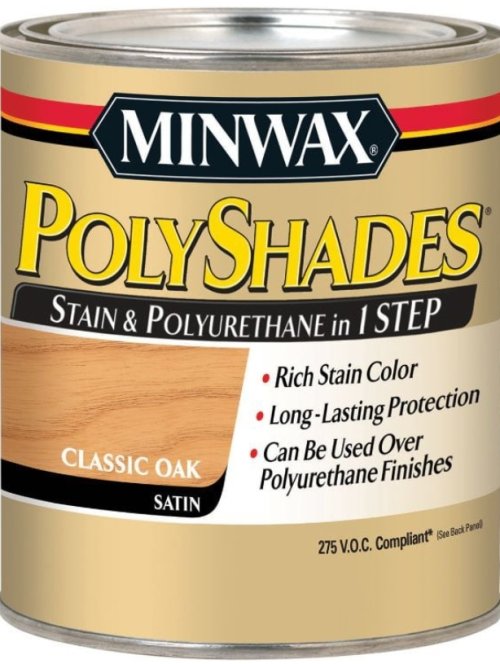

I'm going to be using a piece of butcher block for a work/ reloading bench. I wanted to somewhat protect the surface from gun cleaning chemicals, stains, etc so I picked up some Minwax Polyshades. Surface was sanded and cleaned before applications and product stirred thoroughly but I keep ending up with air bubbles trapped under the coat. I've tried using a brush,foam brush,low nap roller, and a foam roller . Foam roller was the worst, low nap roller produced the least offensive finish. At this point I'm three coats into it and regretting not leaving it unfinished. Any suggestions on applying a smoother finish?

-I'm not interested in spraying it at this point, but that's how I should have approached it from the get go. View attachment 281180View attachment 281181View attachment 281183View attachment 281185View attachment 281186