grizzly63

Well-known member

300 WM 225 Eldm Magpro 3.700 coal 2889fps so far.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Mine is a SFii, fantastic rifle.A late edition end of the line Rem sendero. Tried to get it fixed twice. Third time they gave me a different end of the line rifle. It has this much freebore. I installed a Wyatts long box with the use of a Dremel. Not anything like P. Ham does but it works. I pushed them faster tonight as I'm just on the edge of pressure. Probably in the 2930-50 range. Didn't bring the chrono along tonight. Shooting some larger groups to prove or disprove what I'm getting. Not the 30 shot groups others suggest, just enough to make believe what I am getting is consistent. It currently is about hunting temps now. I am not jamming the lands.

some people are luckier than othersMine is a SFii, fantastic rifle.

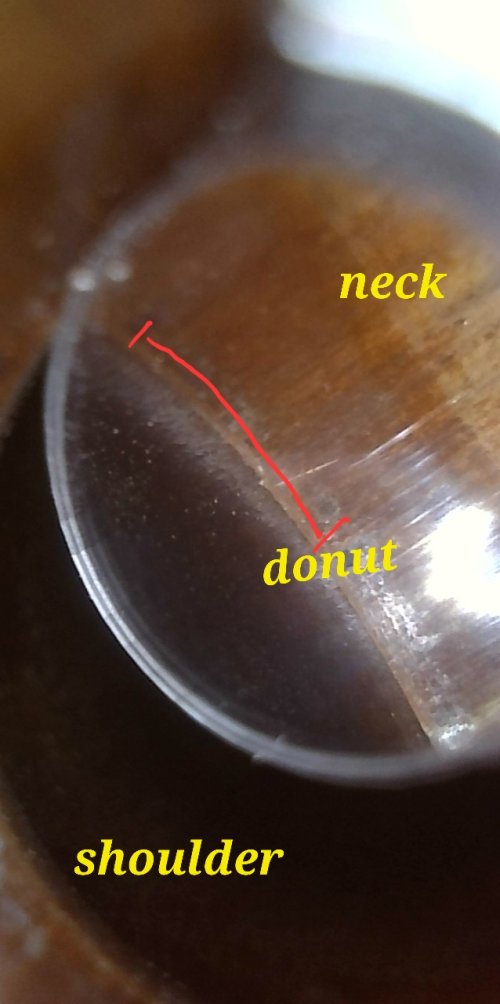

Where the inside neck meets the shoulder junction. Brass eventually flows from the shoulder to the inside of the neck creating a ring or "donut" at the junction. If you've ever seated bullets and felt more resistance or friction about halfway through the stroke, it's most likely a donut. The end cutter is caliber specific and only removes the donut, without cutting the inside of the neck. Maybe someone else can come along and give a little bit better description.OK, whats the dreaded donut? Is that the point where the brass is stretching and closer to the end of serviceable life ?

Have you ever personally experienced case head separation, Or suspected incipient separation?That makes sense. If you full size, does it prevent this? I was thinking more along the lines of a case separation that shows up first as I shiny ring slight above a belted magnum belt.

Those terminal Ascent bullets are really hard to come across and almost as spendy as loaded ammo. When you find them, stock up....Reloading 7mm with Hornady CX 150gr and H4831SC. 3175 fps. Also loading 308 Win with Federal Terminal Ascent 175gr and Varget. 2600 fps.

Are you forming those from .45-70?33 WCF. I am going to do some hunting with it, maybe start with bear this spring.

View attachment 363335

Yes, I bought some new Starline 45-70 and annealed them first and then ran them in a seating die but not quite full depth, then in the 33 fl die. I did 50 and never lost one.Are you forming those from .45-70?

I’m following for results!View attachment 363369

.338-06 ladder test with 190gr. Hammer HHTs and H4895, Norma brass and CCI BR-2 primers.