View attachment 295178

Maybe an ejector mark on the first “R” in Sierra?

Looks like close to a pierced primer too. You have some pressure issue going on for sure.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

View attachment 295178

Maybe an ejector mark on the first “R” in Sierra?

I've thought the primers seemed a bit flat for the entire year and a half I've had the gun, but without any sticky extraction and not trusting myself at reading pressure signs I wrote it off as nothing. It seems like an odd coincidence with the new stock, but I'm inclined to agree with you that it doesn't make much sense that it could be the stock. Not knowing usage/cleaning history but knowing the gun sat for years before it was given to me, it seems like buildup is maybe the likeliest candidate. But either way, I think a trip to a smith is in order just to rule out any other issues.Primers in general look really flat. It does seem like you’ve got significant pressure signs.

I haven’t had an issue like that but only thing I can think of is soaking your throat good with boretech c4 carbon solvent, then scrubbing it. Then doing it again. A gunsmith or buddy with a bore scope would be a good step too.

Have a hard time seeing how the stock could be the cause.

I use a 28 gauge shotgun bore brush to scrub my 30-06 chamber. Brake cleaner fluid works well for loosening carbon build up but wear gloves and remove the action from the stock. This is factory ammo so I don't see the loads as being overly hot. Looks like it could be headspace issue. Try defouling carbon first, then take it to a gunsmith to check with go-no-go gauges. He shouldn't charge much for that and can do it quickly while you watch. Just call ahead and make sure he has gauges for your caliber. They can be rented on line for a couple of bucks. You could easily do it yourself. All it involves is closing the bolt on the two gauges. If the headspace is off that would pretty much indicate the gun had been improperly rebarreled or possibly someone changed bolts. Also, as I said earlier, if the bolt is not closing in the same position as it did with the old stock, that will change the head space. Here's how to check. Close the bolt on new stock. Use a colored sharpie to mark a pointer on the bolt and the receiver at the front of the ejection port. Remove the action and put it back in the old stock. Close the bolt. Do the marks line up? I'm thinking they won't. Given what's happening to your primers, I'm thinking the new stock is allowing the bolt to overturn when locking. You can fix this by adding some filler to the bottom of the bolt handle channel in the stock. A better fix would be to have a gunsmith fix the headspace. He can either build up the edge of the receiver where the bolt handle rests on it or remove the barrel and trim the receiver as needed. If the marks do not align, and I'm betting they won't, it is a curiosity how this gun ever got out of the plant like that. The bolt should lock into position in the same place whether it's on the stock or removed from it or placed in a different stock.I've thought the primers seemed a bit flat for the entire year and a half I've had the gun, but without any sticky extraction and not trusting myself at reading pressure signs I wrote it off as nothing. It seems like an odd coincidence with the new stock, but I'm inclined to agree with you that it doesn't make much sense that it could be the stock. Not knowing usage/cleaning history but knowing the gun sat for years before it was given to me, it seems like buildup is maybe the likeliest candidate. But either way, I think a trip to a smith is in order just to rule out any other issues.

I like the sharpie idea - tried it and the marks line up perfectly with either stock (or no stock). Factory two-letter code on the barrel indicates manufacture in August of 1930, 1974, or 2004. Given my father-in-law was born in 56 and he's had the gun for a long time, I'm going with 1974, but either way it's factory original barrel and I doubt the bolt has been replaced.I use a 28 gauge shotgun bore brush to scrub my 30-06 chamber. Brake cleaner fluid works well for loosening carbon build up but wear gloves and remove the action from the stock. This is factory ammo so I don't see the loads as being overly hot. Looks like it could be headspace issue. Try defouling carbon first, then take it to a gunsmith to check with go-no-go gauges. He shouldn't charge much for that and can do it quickly while you watch. Just call ahead and make sure he has gauges for your caliber. They can be rented on line for a couple of bucks. You could easily do it yourself. All it involves is closing the bolt on the two gauges. If the headspace is off that would pretty much indicate the gun had been improperly rebarreled or possibly someone changed bolts. Also, as I said earlier, if the bolt is not closing in the same position as it did with the old stock, that will change the head space. Here's how to check. Close the bolt on new stock. Use a colored sharpie to mark a pointer on the bolt and the receiver at the front of the ejection port. Remove the action and put it back in the old stock. Close the bolt. Do the marks line up? I'm thinking they won't. Given what's happening to your primers, I'm thinking the new stock is allowing the bolt to overturn when locking. You can fix this by adding some filler to the bottom of the bolt handle channel in the stock. A better fix would be to have a gunsmith fix the headspace. He can either build up the edge of the receiver where the bolt handle rests on it or remove the barrel and trim the receiver as needed. If the marks do not align, and I'm betting they won't, it is a curiosity how this gun ever got out of the plant like that. The bolt should lock into position in the same place whether it's on the stock or removed from it or placed in a different stock.

I seriously doubt pressure and headspace issues from bolt handle/stock contact unless the bolt is seriously out of battery. To determine if there were a headspace issue from this, you could compare "before" fired brass vs "after" fired brass with a L.E. Wilson case gage or comparator. You could use Forster headspace gages in the stock and out of the stock, but now you are getting into spending more money on diagnostics.Looking at this again, the front (barrel-end) and back of the bolt handle do not contact the stock; however, the underside does sit flush against the stock. Could there be an issue where the bolt isn't quite rotating closed all the way but the rifle will still fire?

The easiest way to clean your chamber is to get one of those cheap 3 piece Hoppes rods and use the front third with a 20 gauge cotton bore mop [buy several] and a little Ronsonol lighter fluid. With a light application of Ronsonol work the mop in the chamber as necessary. You can clean the mop by rubbing in some liquid dish detergent and rinsing it well under a light stream of warm water. Similarly you can clean the chamber neck and throat with a 1 3/4 patch in the needle eye jag from your Hoppes kit. Rubbing alcohol may work as well as the Ronsonol too.Just optical

Sorry about the confusing pics, those are just shadows from the shells being directly under the led cabinet lights. Other than the tiny scrape in the single case I posted and the 2 smudge-looking dots just below the belt on the left 2 pieces in the pic you referenced, I don’t see any new marks on fired brass that weren’t there before.

I cleaned the chamber with hoppe’s no 9 and lots of dry patches after using a handgun push-rod I had to get more contact with the outside chamber surfaces. But I’ll be the first to admit I don’t know a lot about proper cleaning technique - a couple passes with solvent and a few clean patches had been the extent of my annual cleaning of the bore up to this point.

Paper clip works tooYou can make a redneck incipient separation gage by bending a coat hanger or ice pick with a little hook on the end. You can feel the ring inside the case quite easily with this. View attachment 295248

Per said redneck gage, there doesn't seem to be case head separation on the case that stuck in the action or any of the other spent brass. May be another optical illusion from light in the pictures... I can definitely feel a little ridge just past the belt on the outside of the case, but inside the case it's smooth.You can make a redneck incipient separation gage by bending a coat hanger or ice pick with a little hook on the end. You can feel the ring inside the case quite easily with this. View attachment 295248

Are you letting things cool off between shots? Seems like a warm chamber after a few shots might be heating the powder enough to cause over pressure. I have 3 [IIRC last production run before closing] Remington 700 left hand actions starting with serial # RR. These are known to have the bolt handle radially misplaced with the result that you have little or no primary extraction. They [2 out of 3] are ok with normal loads, but with warm or hot loads either the bolt has to be tapped back or the case sticks in the chamber.I was intending to try that the next time I'm able to make it back to the range, but the stuck case has me questioning whether I should mess with it anymore or just take it to a smith.

Sticky extraction seems to be pretty consistent between first shot and follow-up shot(s).Are you letting things cool off between shots? Seems like a warm chamber after a few shots might be heating the powder enough to cause over pressure. I have 3 [IIRC last production run before closing] Remington 700 left hand actions starting with serial # RR. These are known to have the bolt handle radially misplaced with the result that you have little or no primary extraction. They [2 out of 3] are ok with normal loads, but with warm or hot loads either the bolt has to be tapped back or the case sticks in the chamber.

Your case sticking likely means an over pressure situation at that time. Not a desirable thing if you need a second or more followup shot.

Contact Dan Armstrong at Accu-tig.Sticky extraction seems to be pretty consistent between first shot and follow-up shot(s).

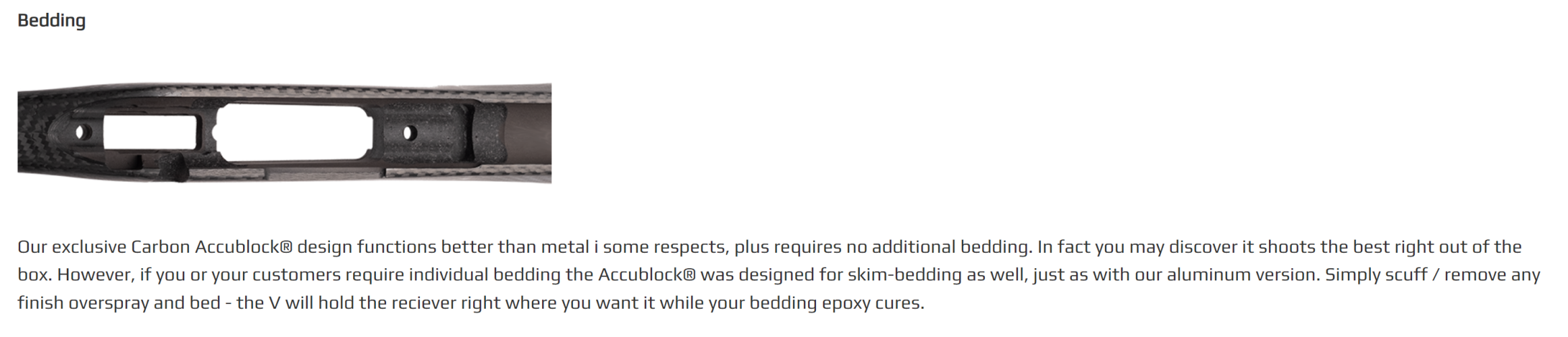

The stocky's CF stocks have a composite bedding block, so I guess closer to full bed than pillars?Does this new stock have a full aluminum bed or just pillars?

Full bed stocks can actually warp an action. I have an M77 mkii that had a "sticky" bolt after torquing it into a Hogue full bed stock.

Worked fine when I put it back into the factory stock.

Careful bed job on the new stock fixed it. Remember not to torque the screws when glass bedding, just want to bottom out the action and get full contact.

Before running off to a gunsmith, I suggest opening up the area in the stock around the Timney trigger. Compare this opening for the two stocks. I strongly suspect that's where the binding is occurring. Timney triggers are generally attached with a pivot pin and a hex head tightening screw. Sometimes if that hex head screw is overtightened the sear binds. Might want to loosen that tightening screw and then take it back down to where it's just tight enough to hold the trigger assembly in position. Anyway, I'm thinking rather than the overtightened screw pushing up on the trigger assembly against the bolt, your new stock is doing it. You can use a Dremel tool with carving bit to open up the trigger opening in the stock.Last update for a while: I had the action installed back in the wood stock for OH’s sharpie test, so I ran out to some public a couple miles away and fired one round. No resistance lifting the bolt and much less sticky extraction, but maybe a tiny bit - sometimes you’re looking so hard for something that you make it exist but hard to be sure. The primer still looks a bit flat but not cratered like the one that stuck.

View attachment 295387

I’m still going to take it to a smith to get the chamber and headspace checked before any more shooting, but it seems like the carbon stock must be warping the action slightly so I’ll be bedding it as soon as I have time.

May be a few weeks til I have everything ironed out but I’ll update with any findings from the gunsmith and post-bedding shooting. Thanks everyone for your insight!