perma

Well-known member

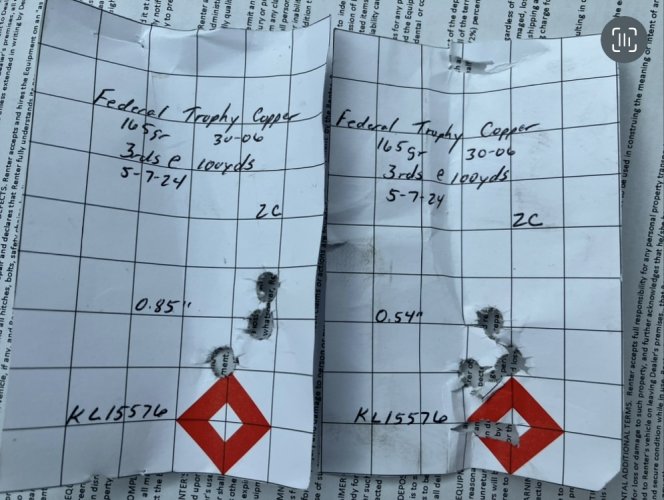

BEFORE you try ANY copper bullet.

YOU HAVE to clean your bore down to Bare steel.

This step is VERY important.

Copper bullets will not shoot to their full potential, shooting over Gilding metal fouling. Trust me on this. I have no idea why but it has been proven multiple times. All my rifles shot copper better after a full cleaning.