Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metalworking Hunttalkers!

- Thread starter p_ham

- Start date

BrentD

Well-known member

Who knew there such things as heirloom jackstands? But there you have it. Sweet.My son sent me this picture today. It's one of the jack stands I made in a highschool shop class in 1966 or 68! The others in the class laughed at me because they are 2' tall collapsed. I drove a pickup and the rest had a variety of other pieces of junk. Theirs were in the 8-12" height.

I used these for years and years then my son latched on to them probably around early 90's. Now my grandson uses them. They straighten them a little and powder coated them a couple years ago. I'm very proud my kid and grandson are still using them 50+ years later! View attachment 266197

Redmt

Well-known member

I told my kid our legacy is blood, grease and jack stands.Who knew there such things as heirloom jackstands? But there you have it. Sweet.

Hem

Well-known member

Adult Ed welding class dives right in with hands on...but I needed more background.

Side note: I bought a welder hood with the electronic darkening. First class I had the dial set at 10...no problem. Second class tried 9.5 to see if it would slightly allow an outline of the plate steel practicing beads on. My eyes are still irritated four days later.

Side note: I bought a welder hood with the electronic darkening. First class I had the dial set at 10...no problem. Second class tried 9.5 to see if it would slightly allow an outline of the plate steel practicing beads on. My eyes are still irritated four days later.

Redmt

Well-known member

9.5 is a very minor difference. What brand of hood did you get?Adult Ed welding class dives right in with hands on...but I needed more background.

Side note: I bought a welder hood with the electronic darkening. First class I had the dial set at 10...no problem. Second class tried 9.5 to see if it would slightly allow an outline of the plate steel practicing beads on. My eyes are still irritated four days later.View attachment 266333

BTW, lay some sliced potatoes on your eyes like using an eye patch. 5-10 minutes and you should be back to normal.

Hem

Well-known member

Thanks Redmt.9.5 is a very minor difference. What brand of hood did you get?

BTW, lay some sliced potatoes on your eyes like using an eye patch. 5-10 minutes and you should be back to normal.

I've been having difficulty getting the arc started . Sometimes it takes 6-8 tries.

Mask gets slightly out of sync with the repeated tries. ...plus we are basically in our welding stations for better than two hours practicing.

I'll try the potato remedy.

p_ham

Well-known member

Adult Ed welding class dives right in with hands on...but I needed more background.

Side note: I bought a welder hood with the electronic darkening. First class I had the dial set at 10...no problem. Second class tried 9.5 to see if it would slightly allow an outline of the plate steel practicing beads on. My eyes are still irritated four days later.View attachment 266333

Turn your heat up a touch to help start your arc. You'll have to adjust how fast you're moving a little.Thanks Redmt.

I've been having difficulty getting the arc started . Sometimes it takes 6-8 tries.

Mask gets slightly out of sync with the repeated tries. ...plus we are basically in our welding stations for better than two hours practicing.

I'll try the potato remedy.View attachment 266344

np307

Well-known member

I have one of those that I use around the house as a backup or when I don't want to get the lens on my 3350 dirty. It's a good basic hood, but it's definitely not that clear. A lot of being able to see the base material has to do with what kind of ambient light you have.Thanks Redmt.

I've been having difficulty getting the arc started . Sometimes it takes 6-8 tries.

Mask gets slightly out of sync with the repeated tries. ...plus we are basically in our welding stations for better than two hours practicing.

I'll try the potato remedy.View attachment 266344

What kind of rod are you practicing with?

Redmt

Well-known member

Turning up the amps may help. Before changing settings try drag starting your rod ,sort of like striking a match. Obviously do it on a chunk of scrap. Another thing is that different rods have very different behaviors. A small diameter 60 series rod will strike much easier than a larger diameter 70 series rod. Another thing with a 7018 series rod is that if you stick it, the flux will crack and break off. That can create more strike problems for you. PLUS!!!! a 7018 rod needs a solid contact making a 45* match strike type start nearly impossible as you need to be within about 15* of vertical. You'll get it. The only way to learn is to burn rod.Thanks Redmt.

I've been having difficulty getting the arc started . Sometimes it takes 6-8 tries.

Mask gets slightly out of sync with the repeated tries. ...plus we are basically in our welding stations for better than two hours practicing.

I'll try the potato remedy.View attachment 266344

Something else about your hood. I'm not familiar with the Lincoln hood. If the auto darkening has the tiniest bit of lag, you'll get flash burn and never realize it until the next day. I use a Jackson True sight. Its one of the higher end hoods without getting into the 5-600 dollar range.

Hem

Well-known member

Using 7018 at a 15 degree. Seems like it sticks most times before I can react.Turning up the amps may help. Before changing settings try drag starting your rod ,sort of like striking a match. Obviously do it on a chunk of scrap. Another thing is that different rods have very different behaviors. A small diameter 60 series rod will strike much easier than a larger diameter 70 series rod. Another thing with a 7018 series rod is that if you stick it, the flux will crack and break off. That can create more strike problems for you. PLUS!!!! a 7018 rod needs a solid contact making a 45* match strike type start nearly impossible as you need to be within about 15* of vertical. You'll get it. The only way to learn is to burn rod.

Something else about your hood. I'm not familiar with the Lincoln hood. If the auto darkening has the tiniest bit of lag, you'll get flash burn and never realize it until the next day. I use a Jackson True sight. Its one of the higher end hoods without getting into the 5-600 dollar range.

Flash burn sounds about right. Both eyes.

Redmt

Well-known member

I'm guessing your doing a vertical poke at it. Try a 45* drag starting. Gradually straighten your angle moving your hand in a pendulum type arc. You'll get used to the strike point that works for you. You'll find it becomes natural. A restrike with 7018 is a bit easier. Use your thumb to break back the flux on one side. You'll see that the rod has formed a pocket with flux extending past the rod.

Hem

Well-known member

I'll give your explanation a whirl.I'm guessing your doing a vertical poke at it. Try a 45* drag starting. Gradually straighten your angle moving your hand in a pendulum type arc. You'll get used to the strike point that works for you. You'll find it becomes natural. A restrike with 7018 is a bit easier. Use your thumb to break back the flux on one side. You'll see that the rod has formed a pocket with flux extending past the rod.

Thanks for the advice!!

Redmt

Well-known member

Remember advice is worth exactly what you paid for it,,,,,,I'll give your explanation a whirl.

Thanks for the advice!!

millerkiller77

Well-known member

+1 on the potato hack for flash burn.

Flash burn feels like rubbing a handful beach sand into your eyes for 12 hours. 10/10 don't recommend getting it twice...

Flash burn feels like rubbing a handful beach sand into your eyes for 12 hours. 10/10 don't recommend getting it twice...

Hem

Well-known member

Worried there could be issues with potatos?Remember advice is worth exactly what you paid for it,,,,,,

Redmt

Well-known member

Don't cook the 'taters first.Worried there could be issues with potatos?

Hem

Well-known member

potatoes? Not THAT bad^^ thank goodness. Just sensitive, especially using smartphone.+1 on the potato hack for flash burn.

Flash burn feels like rubbing a handful beach sand into your eyes for 12 hours. 10/10 don't recommend getting it twice...

I think I might err on the side of caution and get a old fashion mask...up or down.

Also might get a small fan to move air in the booth.

Hem

Well-known member

Anyhow, this Wednesday in class I might try MIG .

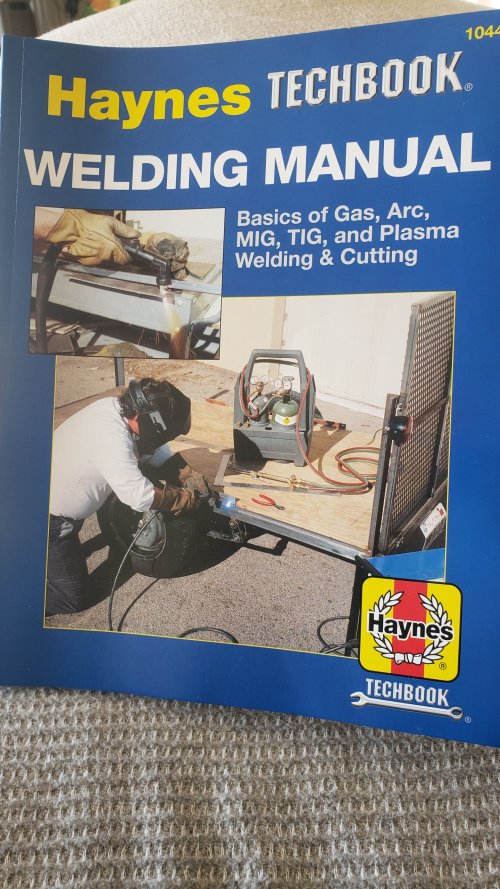

The manual i purchased has been a good read to spell out basic concepts of welding which haven't been covered in this class.

I think if I can get a handle on stick welding and MIG I should be covered for the basics I am interested in.

Getting a welder for my shop will kick the door open . Already starting to eye metal scraps.

The manual i purchased has been a good read to spell out basic concepts of welding which haven't been covered in this class.

I think if I can get a handle on stick welding and MIG I should be covered for the basics I am interested in.

Getting a welder for my shop will kick the door open . Already starting to eye metal scraps.

Brandon270

Well-known member

Similar threads

- Replies

- 37

- Views

- 4K