millerkiller77

Well-known member

I fixed it for you. You're welcome.Make sure to keep your GAT handy, and possibly a BOOM stick. Don't want those nasty things THRIVING around on deck!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I fixed it for you. You're welcome.Make sure to keep your GAT handy, and possibly a BOOM stick. Don't want those nasty things THRIVING around on deck!

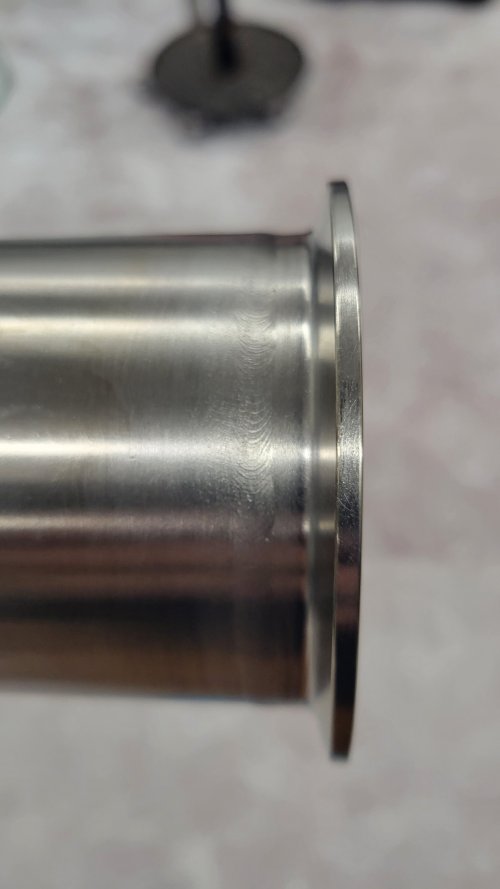

Is this a bottling facility?Well I hit time and a half today. Still 2 long days left this week. The bad news is that we are behind schedule, partly because there was another section of piping that also had to tie into the pumps that we weren't told about. The good news is that problems with other systems have pushed the restart date back so we gave some breathing room. I'm doing most of the fitting while my boss does the welding. I have been getting to weld some ferrules on though. View attachment 275499

Dairy plantIs this a bottling facility?

does your bosses welds look better then yours? Looks like you know what your doing.Well I hit time and a half today. Still 2 long days left this week. The bad news is that we are behind schedule, partly because there was another section of piping that also had to tie into the pumps that we weren't told about. The good news is that problems with other systems have pushed the restart date back so we gave some breathing room. I'm doing most of the fitting while my boss does the welding. I have been getting to weld some ferrules on though.

1) he's certified and I'm not yet, which matters as these are product linesdoes your bosses welds look better then yours? Looks like you know what your doing.

That's the quality of an automated circular welder. That's some fantastic welding! Almost indistinguishable!Well I hit time and a half today. Still 2 long days left this week. The bad news is that we are behind schedule, partly because there was another section of piping that also had to tie into the pumps that we weren't told about. The good news is that problems with other systems have pushed the restart date back so we gave some breathing room. I'm doing most of the fitting while my boss does the welding. I have been getting to weld some ferrules on though. View attachment 275499

Thanks. If you look closely you can see the tell-tale marks of walking the cup but nothing you can do to avoid that (other than freehanding it, which wouldn't look so consistent)That's the quality of an automated circular welder. That's some fantastic welding! Almost indistinguishable!

Very nice.

whatever dude, walk that cup. As long as its sealed up and solid. Normal humans would ever even notice.Thanks. If you look closely you can see the tell-tale marks of walking the cup but nothing you can do to avoid that (other than freehanding it, which wouldn't look so consistent)

Oh trust me, I'm very happy with the welds I'm making. I know some things that I need to improve on, but overall my welds are as good as or better than most of the stuff we replace.whatever dude, walk that cup. As long as its sealed up and solid. Normal humans would ever even notice.

im surprised with pharmaceutical, but nuclear makes sense. Not a whole lot of room for error in that line of work.Oh trust me, I'm very happy with the welds I'm making. I know some things that I need to improve on, but overall my welds are as good as or better than most of the stuff we replace.

Believe it or not, some pharmaceutical and nuclear jobs won't let you walk the cup because of those track marks.

Yeah lots of pharma jobs don't allow files or wire brushes either. Nothing that could scratch the tubing. Stands can't allow carbon steel to contact the stainless. They don't mess around either.im surprised with pharmaceutical, but nuclear makes sense. Not a whole lot of room for error in that line of work.

wow. That is broke broke. Did that crack go all the way through?Here's motor grader frame crack I started repairing today.

View attachment 276049

Looks like is been "repaired" at least once beforeHere's motor grader frame crack I started repairing today.

View attachment 276049

V it out. Blow out the old crap. Drill the ends. Weld the snot out of it and move on. I'm going to guess the original weld was too hot without any kind of preheat to the area.Here's motor grader frame crack I started repairing today.

View attachment 276049