Don Fischer

Well-known member

- Joined

- Jun 27, 2017

- Messages

- 3,183

Much appreciated, cahunter

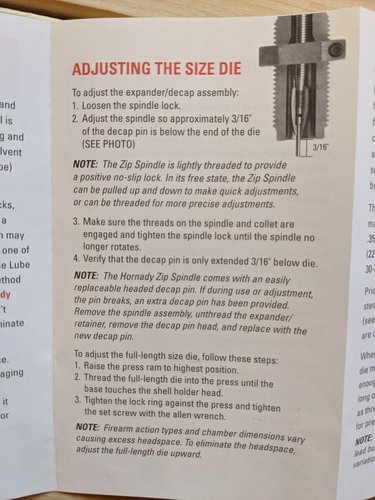

I've sourced the problem to the sizing die - the manual says to screw it down until it touches the shell holder, but that didn't provide enough bump. I turned the die an additional 1/16 turn and my cases are fitting much better and the bolt is closing as expected.

I'm planning to load up more of the 54 gr at the current seating depth, then have a few with seating depth adjusted each way.

Thanks for the input and responses everyone, always good to touch base and get some different opinions

cahunter. Maybe you should read his post again. His words, "manual say's screw it down till it touch's the shell holder..." I've never seen directions like that. Every set I've ever seen say's that and then screw down , either another 1/8 or 1/4 turn more. Guessing he read the direction's wrong! That is a newbe mistake, why should the die go down farther than the shell holder? Spring in the press!

Now why pop up all of a sudden? Well he actually wasn't FL sizing. You neck size with an FL die and the first time, maybe first two time's the case's will chamber, Then do the same thing again and the case wont chamber. Reason being the case has finally filled out the case to capacity not allowing it to chamber again. When early on I neck Sized with an FL die about every third time I had to FL size again to get the case to chamber. That's probably what he got. But if you set the FL die up to partial size or bump the shoulder, what happens is every time the die is put through the die again it get's re-size completely to where you originally set it. You cannot bump the shoulder without bumping the entire case. If you could there would be a donut around the body/neck junction that would not allow the case to chamber!