I listened to a recent podcast that mentioned the PynchPulley from Wiser Precision. These ultralight pulleys are very nice. With them, you can lift a lot of weight with a fraction of the effort.

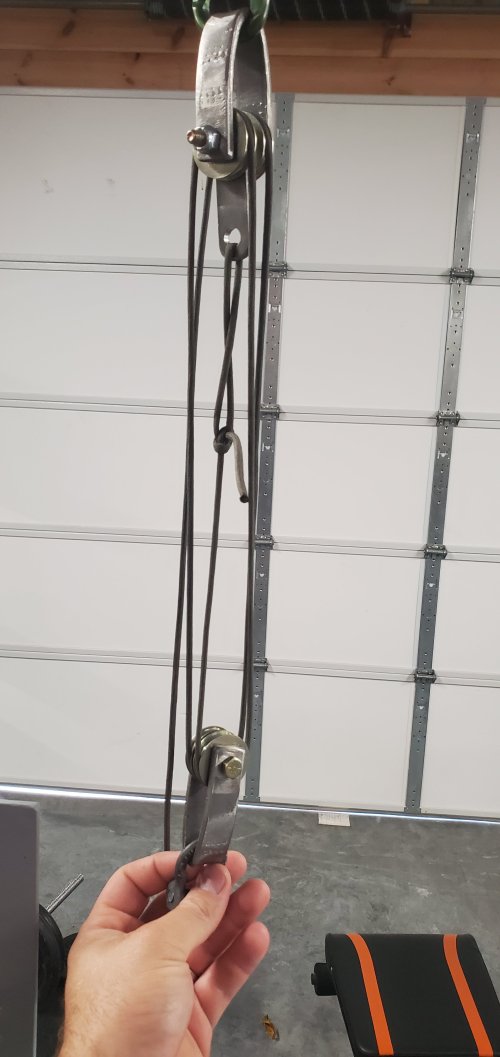

I almost pulled the trigger and thought, what about a motorbike chain as an alternative, DIY hack? Here are my two set-ups, one with 4:1 and the other with 6:1 (the other half of the 6:1 pulleys were in the garage). I tack-welded the 4:1 pulleys to keep them straight, but I don't think this is really necessary.

I researched the breaking strength of a single link of 410 motorbike chain, but all I could find was statistics for the entire chain. To the garage. I stressed the cord with two clamps to test the strength of the chain link and could not get enough weight to break the cord or a single link. This would be helpful to lift an elk up a short cliff or out from underneath a log.

6:1 pulley mechanical advantage: for every 1 pound of force applied, you can lift 6 pounds of weight. With a 700-pound load (entire elk), you would need to apply approximately 116.67 pounds. My 6:1 pulley system is going in my kill kit in case I have an elk under a log or down a short cliff.

A 4:1 pulley mechanical advantage; with a 200-pound load (bone-in quarters and backstraps), you would only need to apply 50 pounds.

I have 2mm Dyneema (440 pound tensile strength) and 550 paracord (550 lb tensile strength). For the attachment points of the load, I doubled the Dyneema for 880 tensile strength, but the weight on each of the pulley's will be considerably lower than 440 pounds each.

I almost pulled the trigger and thought, what about a motorbike chain as an alternative, DIY hack? Here are my two set-ups, one with 4:1 and the other with 6:1 (the other half of the 6:1 pulleys were in the garage). I tack-welded the 4:1 pulleys to keep them straight, but I don't think this is really necessary.

I researched the breaking strength of a single link of 410 motorbike chain, but all I could find was statistics for the entire chain. To the garage. I stressed the cord with two clamps to test the strength of the chain link and could not get enough weight to break the cord or a single link. This would be helpful to lift an elk up a short cliff or out from underneath a log.

6:1 pulley mechanical advantage: for every 1 pound of force applied, you can lift 6 pounds of weight. With a 700-pound load (entire elk), you would need to apply approximately 116.67 pounds. My 6:1 pulley system is going in my kill kit in case I have an elk under a log or down a short cliff.

A 4:1 pulley mechanical advantage; with a 200-pound load (bone-in quarters and backstraps), you would only need to apply 50 pounds.

I have 2mm Dyneema (440 pound tensile strength) and 550 paracord (550 lb tensile strength). For the attachment points of the load, I doubled the Dyneema for 880 tensile strength, but the weight on each of the pulley's will be considerably lower than 440 pounds each.