Dougfirtree

Well-known member

I'm curious how others tinker (or don't) with high ES. I'm trying to make a decision about whether to stick with a loading project for a while longer, or if I should just start over with different components.

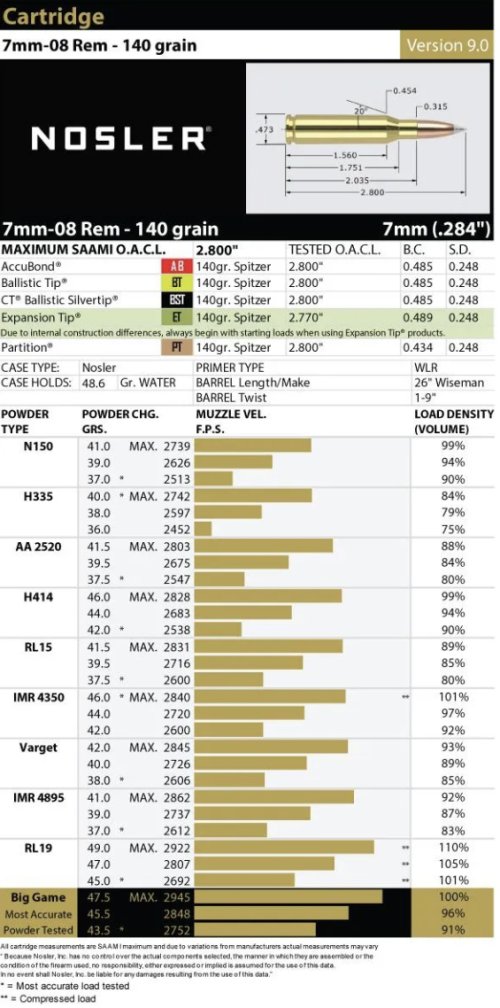

The quick version: I'm trying to work up a new practice load for my 7mm-08. I'm playing with 139 SST's and Big Game powder. I've got one load (46.5 grains @2.8") that is showing some promise in terms of groups at 100 yards. It's a little over an inch and normally, I'd play with COAL now and see if seating the bullet deeper shrunk those groups a bit. However, the ES of velocity is all over the place; well over 100fps.

Have you ever fixed a high ES by tinkering with COAL? Or is that something you've only improved with different powder charges, different components, etc? I guess I don't totally understand the factors that cause a high ES (aside from the obvious one of component consistency).

The quick version: I'm trying to work up a new practice load for my 7mm-08. I'm playing with 139 SST's and Big Game powder. I've got one load (46.5 grains @2.8") that is showing some promise in terms of groups at 100 yards. It's a little over an inch and normally, I'd play with COAL now and see if seating the bullet deeper shrunk those groups a bit. However, the ES of velocity is all over the place; well over 100fps.

Have you ever fixed a high ES by tinkering with COAL? Or is that something you've only improved with different powder charges, different components, etc? I guess I don't totally understand the factors that cause a high ES (aside from the obvious one of component consistency).