riv3rbanks

Active member

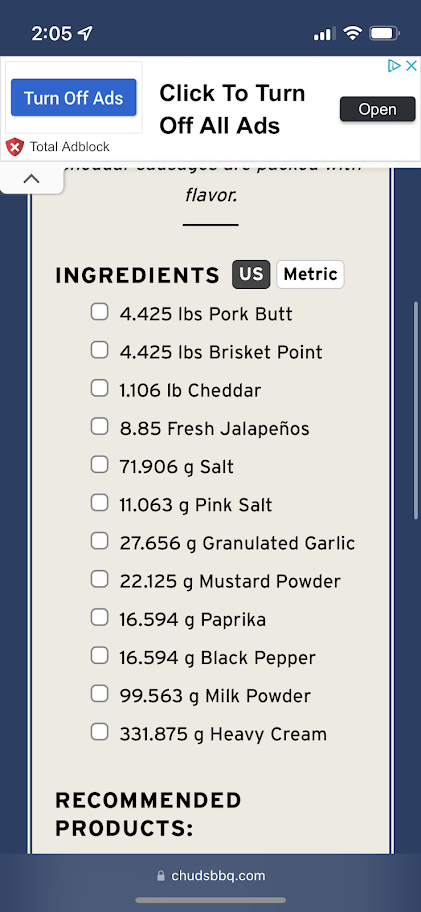

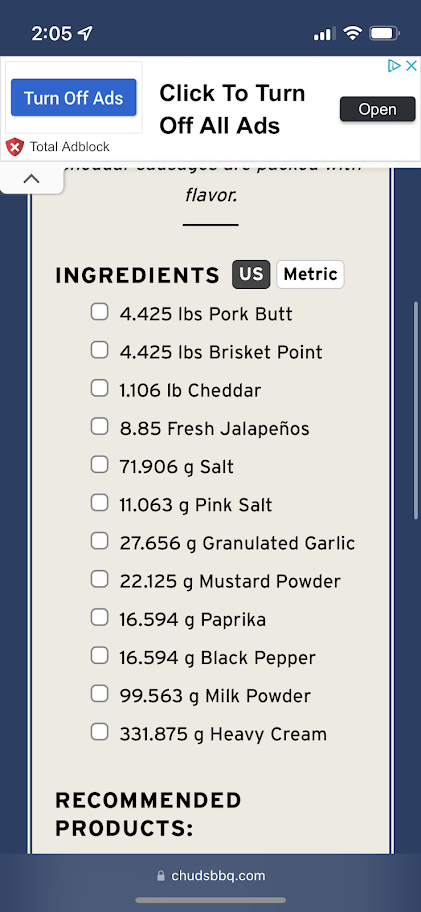

Got to put my new processing equipment to work this winter. I found a few sausage and meat stick recipes that I wanted to try out with some venison I got during bow season. I mixed it with pork butt and some beef tallow trimmings for proper fat ratios. I choose between 75-80% lean and 20-25% fat. In total, I was making 30 lbs of sausage and sticks. Jalapeno cheddar sausage, Texas hot gut sausage, and Kabonoshy meat sticks. This ended up being more than I should've taken on for the first time, but I had some time on my hands with the holidays and got it done.

The grinding process was super easy with my new MEAT! 1hp grinder. I only sent the meat through the coarse plate once and the grinder did it super fast and easily. I kept the meat and grinder parts very cold during the whole process. This was definitely a needed upgrade as I was running a cheaper smaller grinder for the past few years and this process always took forever. Since I was making 3 different recipes and seasoning the meat prior to grinding, I did need to do some cleanup in between grinds. In the future, I will stick with one recipe or do all the grinding and season after the grind.

Next came the mixing and stuffing process. I mix by hand. I used to do this barehanded, but have upgraded to insulated gloves. Gloves allow me to mix long enough to get the proper protein extraction. After mixing a made a small patty to ensure the meat had the flavor I was looking for. I have a 5lb manual crank stuffer and I secure it using some adjustable clamps. 5lb is big enough for me in most cases, but when making this much sausage, I wish I had a 15lb stuffer. Having a manual crank stuffer is much easier as a 1-person method rather than attempting to do this with your grinder. I felt I had much more control over the flow of the meat into the casings.

As for the casings, I still have some learning to do. I used hog casings from PS Seasonings and Oversea casing. I followed the instructions on soaking but kept finding ways to bust my sausage links. I would say I got 1 out of 5 casings to go the whole length. I either need to buy better casings or lower my expectations. For the meat sticks, I went with 19mm collagen casings from LEM. I didn't have many issues with these except getting them on my stuffing tube. I might try a smaller diameter tube the next time.

The whole grind and stuff process with the multiple cleanups in between and the chilling of meat took up pretty much a whole day. Once all the links and sticks were stuffed, into the beer fridge they went to dry and let the meat really absorb the seasonings. If you have a way to hang them in the fridge that would be ideal, but I had limited space and just used cookie sheets lined with paper towels.

The following day I fired up the smokers to cold smoke everything. I was able to do a cold smoke since I included pink salt. Since it was a cool day, I let the sausage hang for a few hours outside. I cold-smoked them at 150-160. Since I had so much I used my stick burner and my camp chef pellet grill. For this type of low temp smoking, I much prefer the stick burner. The pellet grill fire kept burning out and I would have to shut it down and start it up again. I also like more smoke and the stick burner is also best for this. Smoked them until an internal temp of about 150. Took roughly 4 hours.

After the smoke process was finished, into an ice bath everything went to stop the cooking process and firm up the casings. This also provided an opportunity to clean the grill marks from the sausage with a rag. Once chilled I put everything back into the fridge to rest overnight. The next day I vacuum-sealed everything for later use. We had some on Christmas day. Everything turned out tasting great. My favorite is the jap cheddar links (Recipe below).

Knowing how the sausage is made is definitely important to me. I feel much better knowing that high-quality meat and ingredients are going into my food.

The grinding process was super easy with my new MEAT! 1hp grinder. I only sent the meat through the coarse plate once and the grinder did it super fast and easily. I kept the meat and grinder parts very cold during the whole process. This was definitely a needed upgrade as I was running a cheaper smaller grinder for the past few years and this process always took forever. Since I was making 3 different recipes and seasoning the meat prior to grinding, I did need to do some cleanup in between grinds. In the future, I will stick with one recipe or do all the grinding and season after the grind.

Next came the mixing and stuffing process. I mix by hand. I used to do this barehanded, but have upgraded to insulated gloves. Gloves allow me to mix long enough to get the proper protein extraction. After mixing a made a small patty to ensure the meat had the flavor I was looking for. I have a 5lb manual crank stuffer and I secure it using some adjustable clamps. 5lb is big enough for me in most cases, but when making this much sausage, I wish I had a 15lb stuffer. Having a manual crank stuffer is much easier as a 1-person method rather than attempting to do this with your grinder. I felt I had much more control over the flow of the meat into the casings.

As for the casings, I still have some learning to do. I used hog casings from PS Seasonings and Oversea casing. I followed the instructions on soaking but kept finding ways to bust my sausage links. I would say I got 1 out of 5 casings to go the whole length. I either need to buy better casings or lower my expectations. For the meat sticks, I went with 19mm collagen casings from LEM. I didn't have many issues with these except getting them on my stuffing tube. I might try a smaller diameter tube the next time.

The whole grind and stuff process with the multiple cleanups in between and the chilling of meat took up pretty much a whole day. Once all the links and sticks were stuffed, into the beer fridge they went to dry and let the meat really absorb the seasonings. If you have a way to hang them in the fridge that would be ideal, but I had limited space and just used cookie sheets lined with paper towels.

The following day I fired up the smokers to cold smoke everything. I was able to do a cold smoke since I included pink salt. Since it was a cool day, I let the sausage hang for a few hours outside. I cold-smoked them at 150-160. Since I had so much I used my stick burner and my camp chef pellet grill. For this type of low temp smoking, I much prefer the stick burner. The pellet grill fire kept burning out and I would have to shut it down and start it up again. I also like more smoke and the stick burner is also best for this. Smoked them until an internal temp of about 150. Took roughly 4 hours.

After the smoke process was finished, into an ice bath everything went to stop the cooking process and firm up the casings. This also provided an opportunity to clean the grill marks from the sausage with a rag. Once chilled I put everything back into the fridge to rest overnight. The next day I vacuum-sealed everything for later use. We had some on Christmas day. Everything turned out tasting great. My favorite is the jap cheddar links (Recipe below).

Knowing how the sausage is made is definitely important to me. I feel much better knowing that high-quality meat and ingredients are going into my food.