dan.kirkpatrick

Well-known member

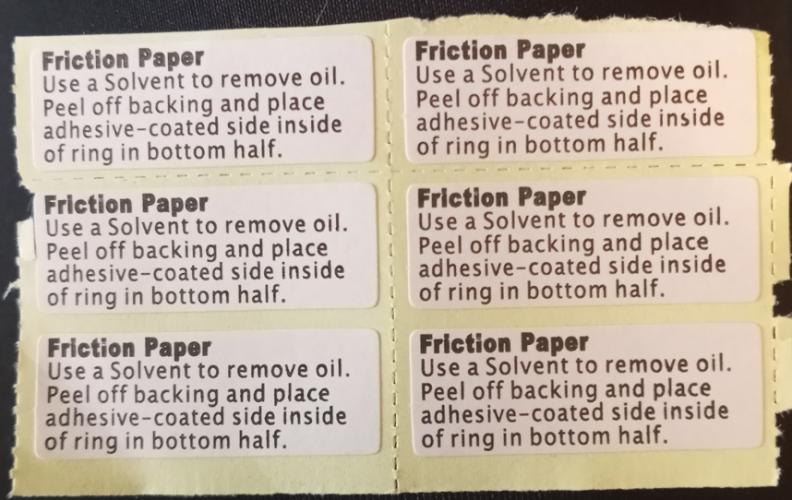

ive got that same wheeler scope honing setup and think its a good idea so it doesnt bind the scope in any ways,,ive never had issues,,im a firm believer in using the{fat wrench} torque wrench on all the screws to proper specs