AIM STR8

Member

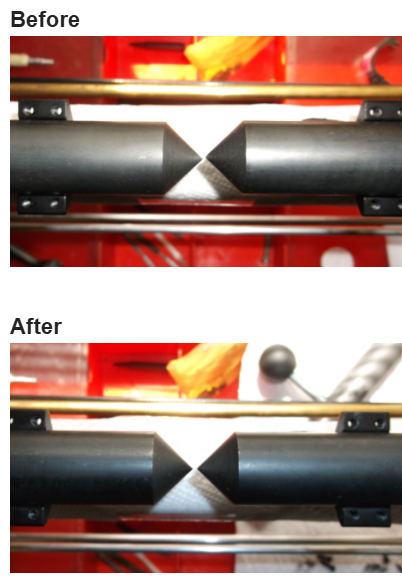

After having the scope rings honed in and properly torqued down I got to wondering what are the chances that the center of the scope and the center of barrel are not co-planar?

Any experience with this?

Any experience with this?