rogerthat

Well-known member

- Joined

- Aug 29, 2015

- Messages

- 2,918

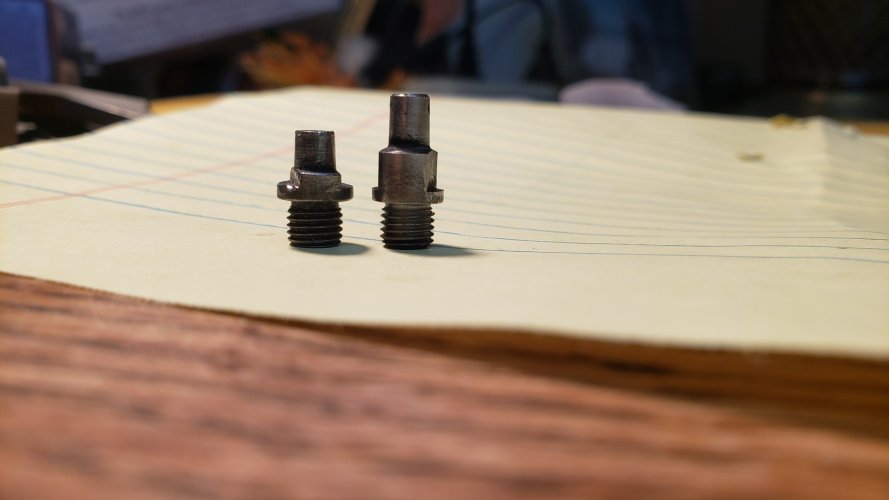

Ok. What am I doing wrong? I have a cva hawkens percussion purchased used on gunbroker. When I first got it. It seemed like the hammer was dragging a little and it would take multiple drops of the hammer to go off. I changed out the nipple. Loosened the screw that goes all the way through the gun and holds the hammer assembly. I oiled up the hammer group and that seemed to help a bunch. I had it loaded up for about 4 days and when I shot yesterday. Took multiple attempts to pop the cap. Should I change out the main spring? I have an extra one or is it more likely something is still in the hammer binding?