So how did they turn out? Lets see the final product.Soda fire on the 13th. Rushing to try and get these done so they can be in that firing. Threw ten tea bowls last night while blasting Tool through the ear buds. Zen & the art of metal.

View attachment 127462

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

February Free Time Fillers

- Thread starter Sawtooth

- Start date

DouglasR

Well-known member

^^

I too am curious to see what type of glaze the humble potter BL chose for these pieces.

I too am curious to see what type of glaze the humble potter BL chose for these pieces.

We've got one more reduction firing for class this week & then I'm moving over to an intermediate class that will focus on cone 10 soda & \reduction firing w/an emphasis on glazing. I've thrown & fired 50 pieces so far this class, with about 20 of them just in the bisque stage still, so I'll likely use those for the next class.

There were hits & misses on the glazing. I went with a mix of Shino, Albany slip & Temmoku glazes with one in Blue Monday for the bowls. Since this was a cone 6 firing, they weren't the true forms of these glazes, but altered for the lower temperature. Still, the results were pretty nice where it worked. I may re-fire the pieces with the white crawl as it didn't perform as hoped for.

Albany slip on the side bowls, with the middle one a Shino

7 of the 8 that survived.

Mugs (Handles are not all that great, I need to practice that more)

A bowl that could double as an anchor. Little heavy in the bottom.

There were hits & misses on the glazing. I went with a mix of Shino, Albany slip & Temmoku glazes with one in Blue Monday for the bowls. Since this was a cone 6 firing, they weren't the true forms of these glazes, but altered for the lower temperature. Still, the results were pretty nice where it worked. I may re-fire the pieces with the white crawl as it didn't perform as hoped for.

Albany slip on the side bowls, with the middle one a Shino

7 of the 8 that survived.

Mugs (Handles are not all that great, I need to practice that more)

A bowl that could double as an anchor. Little heavy in the bottom.

Stay Sharp

Well-known member

I have bought 2 blanks but it isn't as easy as they make it look on Youtube!

Yes it is.

The easy in making knives depends on your shop and if you have the tools for the work. If you have the proper tools, its pretty easy (especially if you buy blanks that are finished and all you are doing is attaching the scales.

pre6422hornet

Well-known member

- Joined

- May 21, 2015

- Messages

- 525

I started making knives a little over a year ago. I buy old sawmill blades and cut them up. 8670 steel .100 thick. It has become a passion of mine. 8670 is very workable. I do all my own heat treating ( built a forge) and leather work. I am experimenting with different etches, finishes and have upgraded some shop tools. Looking for a good anvil currently to begin forging from scratch.

I am proud to say that my knives have been used on over 10 head of big game all over North America by customers. 6 elk, 2 barbary sheep, and 2 mule deer and 2 whitetail. Dozens of birds.

This one is was a prototype that is now a standard. Nice skinner.

Barbary sheep in NM

I have done close to 10 cleavers.

This one was a 9 inch blade kitchen in 52100 steel. Super tough steel.

Three after ferric chloride etch.

Another happy customer.

I am proud to say that my knives have been used on over 10 head of big game all over North America by customers. 6 elk, 2 barbary sheep, and 2 mule deer and 2 whitetail. Dozens of birds.

This one is was a prototype that is now a standard. Nice skinner.

Barbary sheep in NM

I have done close to 10 cleavers.

This one was a 9 inch blade kitchen in 52100 steel. Super tough steel.

Three after ferric chloride etch.

Another happy customer.

Stay Sharp

Well-known member

you did well. Its a joy making a useful tool for others to enjoy. I made this from scratch (O1 tool steel bar stock and moose antler) for a friend that has got a lot of use from it.

I cut the handle from a section of the antler that provided a finger guard.

Then picked a blade form that matched the handle.

Then made an O1 steel blade with a little file work.

Then contoured the brass and added a some ink.

Next I made a sheath with a moose antler image.

I used the tip of the antler as a display base.

These are the pics I got from our friend. He got several diff bucks in diff states.

I cut the handle from a section of the antler that provided a finger guard.

Then picked a blade form that matched the handle.

Then made an O1 steel blade with a little file work.

Then contoured the brass and added a some ink.

Next I made a sheath with a moose antler image.

I used the tip of the antler as a display base.

These are the pics I got from our friend. He got several diff bucks in diff states.

devon deer

Well-known member

All I have is an angle grinder and some files!Yes it is.I wish I had the time to get back into it as much as I used to. I made a ton of custom knives and sheaths since 1982.

The easy in making knives depends on your shop and if you have the tools for the work. If you have the proper tools, its pretty easy (especially if you buy blanks that are finished and all you are doing is attaching the scales.

I bought some O1 steel, it is a steep learning curve, even if that turn out rubbish I'll still post up some photo's

Cheers

Richard

Stay Sharp

Well-known member

All I have is an angle grinder and some files!

I bought some O1 steel, it is a steep learning curve, even if that turn out rubbish I'll still post up some photo's

Cheers

Richard

That is why knife making is hard. You lack the proper tools. O1 tool steel is a great material to work with as you can heat and re-heat without costing a lot of money and it donest mind heating and re-heating. Make sure to temper (stress relive) after quench in oil.

Hertervillian

Well-known member

- Joined

- Oct 23, 2019

- Messages

- 174

Almost ready for hardware. Just need a little cleanup on the hook hangers / line ties.

Hard carved balsa (not blanks). Through Wire. Self painted.

I'll try to get a better photo later. The little goldens are great fishermen catchers.

Hard carved balsa (not blanks). Through Wire. Self painted.

I'll try to get a better photo later. The little goldens are great fishermen catchers.

Northwoods Labs

Well-known member

I spend the time ice fishing and hiking with my dogs. There are some fantastic artists on here, wish I had that skill

Ice fishing, snow shoeing, getting into skiing, tie flies, hit the gym, repair gear, maintain gear, research where to hunt next, plan hunting trips, plan backpacking and fishing trips, plan float trips, try to buy a house, read occasionally, and cook enough to stay alive.

I should probably find a girlfriend...

I should probably find a girlfriend...

Lmwmihunter76

Active member

If you find a girlfriend you wont be able to do as much cool stuffIce fishing, snow shoeing, getting into skiing, tie flies, hit the gym, repair gear, maintain gear, research where to hunt next, plan hunting trips, plan backpacking and fishing trips, plan float trips, try to buy a house, read occasionally, and cook enough to stay alive.

I should probably find a girlfriend...

GrantK

Well-known member

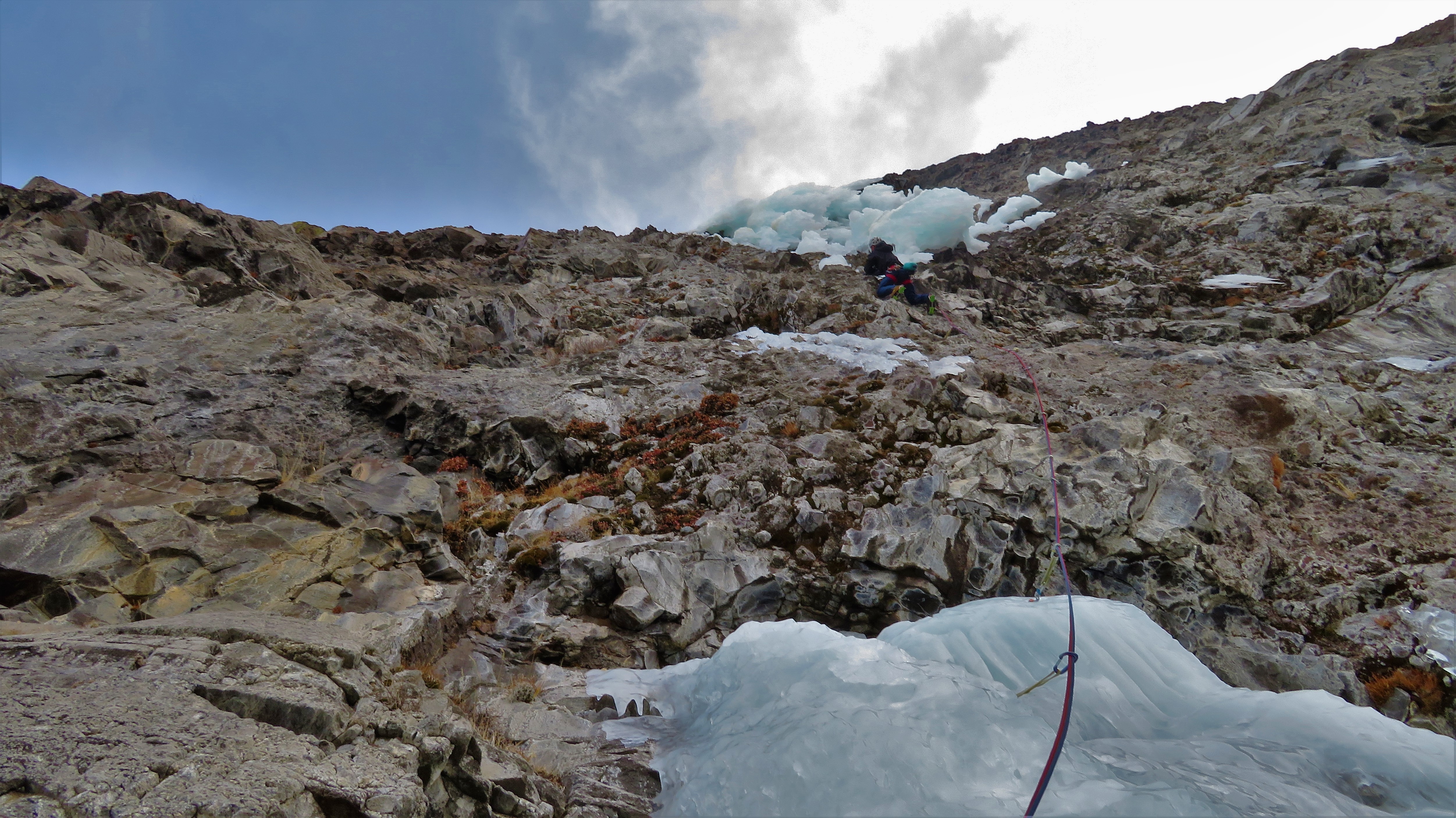

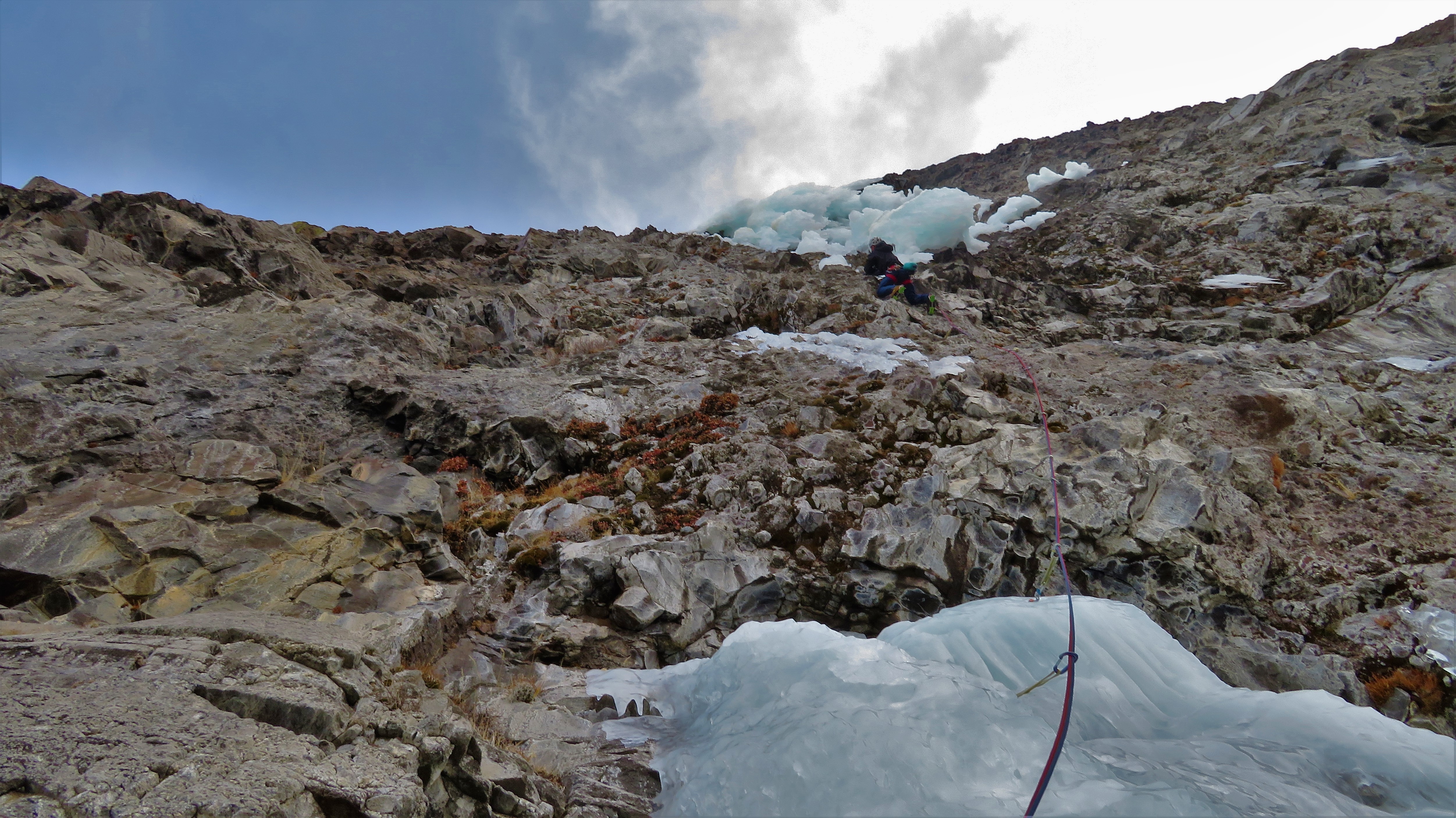

once hunting season is over I usually switch it up and hunt for rare ice...there's some similarity to chasing elk, lots of walking and glassing with a fairly low success rate...

If you find a girlfriend you wont be able to do as much cool stuff

Ideally, the only thing that would change would be that I get company on the trips.

Similar threads

- Replies

- 10

- Views

- 1K