but 2.73 seems seated a little deep to me. Over seating a bullet can cause pressures to do some funny things.

That’s the spec in the Barnes manual.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

but 2.73 seems seated a little deep to me. Over seating a bullet can cause pressures to do some funny things.

Alright, went back to the range today, yesterday there was too much driving rain...

Loaded up everything as before:

First shot I fired was a control shot using some factory federal ammo. No sticky bolt, smooth going in just as smooth ejecting.

- Hornady brass fire once, FL sized and trimmed back to spec

- 44g of BLC2

- 150g TTSX

- Seated the bullet at 2.730 per the groups recommendations

Now first round of the TTSX, bolt sticky. Always happens about with the bolt in the 3/4 position. Pulled out the case and put it back in the chamber, stiff going in, got stuck and had to use the cleaning rod to get it out...

Back to the drawing boards gents... Do we think its a powder issue then??

Alright, back to my Nosler manual... Here you see the trim length at 2.015, additionally, I use a quick trim device for .308 that is also set at the same value, so I can't shorten that up if I want to....I'm no expert, but I've just been following my manual from nosler, is this not correct? View attachment 106626View attachment 106626

Alright, back to my Nosler manual... Here you see the trim length at 2.015, additionally, I use a quick trim device for .308 that is also set at the same value, so I can't shorten that up if I want to....

I went and cheeked the SAAMI definition for the 308, matches the Nosler book for case length. And assuming my gun would be built to the saami standard there should be no chance of crimping on the bullet, right?

I'll run through how I set that up when I get back home, I will say when I pulled the bullet on one of the ttsx bullets it was pretty dang hard to remove compared to a smooth lead bullet.Actually, 2.015 is the maximum case length. The trim to length is always shorter to allow for case stretching over several loadings.

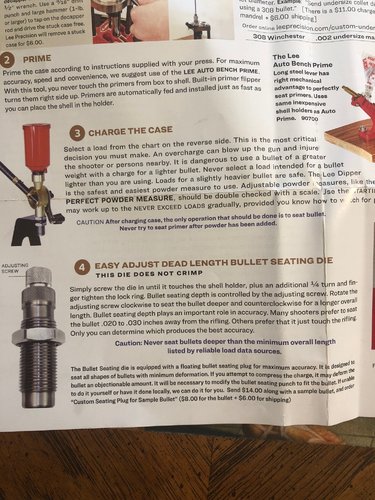

How are you setting up your seating die? If done incorrectly it could be crimping the neck.

If everything is set up correctly, it could be the dies. I had a bad one for a .243.

Is this your first attempt reloading for this rifle? Have you reloaded for other rifles?

Alright, back to my Nosler manual... Here you see the trim length at 2.015, additionally, I use a quick trim device for .308 that is also set at the same value, so I can't shorten that up if I want to....

I went and cheeked the SAAMI definition for the 308, matches the Nosler book for case length. And assuming my gun would be built to the saami standard there should be no chance of crimping on the bullet, right?

Wrong! If your seating die is set up wrong it may well crimp the bullet!

Thinking just the seating die, nothing else? Particular brand to try?Get a new die. If that's not the issue you can sell it.

Thinking just the seating die, nothing else? Particular brand to try?

Think its worth calling Lee's and see if they have any insight?

Just measured the factory ammo with the bullet still in it, looks like its about 2.004"Have you measured out your full length resized cases compared to the factory ones?

Specifically where the crimp would be where the case meets the bullet.