Redmt

Well-known member

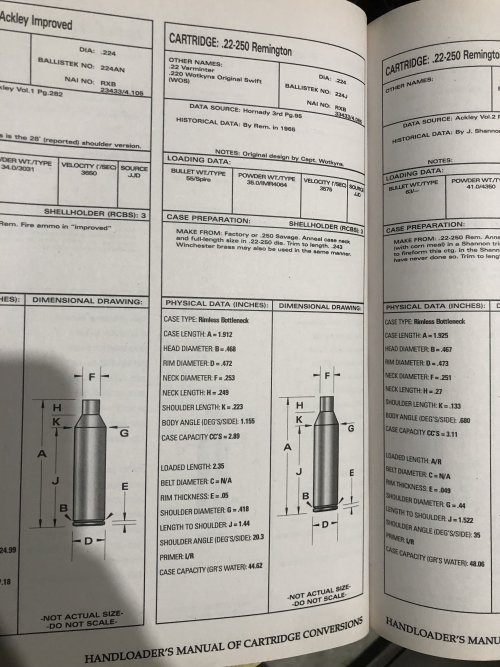

It seems there's no 22-250 brass on the planet that isn't made from gold. Has anyone successfully been able to convert another case, (308) to 22-250? I've read numerous articles that haven't been very successful and one that said it's easy peasy. None really give an in depth method. Has anyone here done it and what are your recommendations for doing it?