Addicting

Well-known member

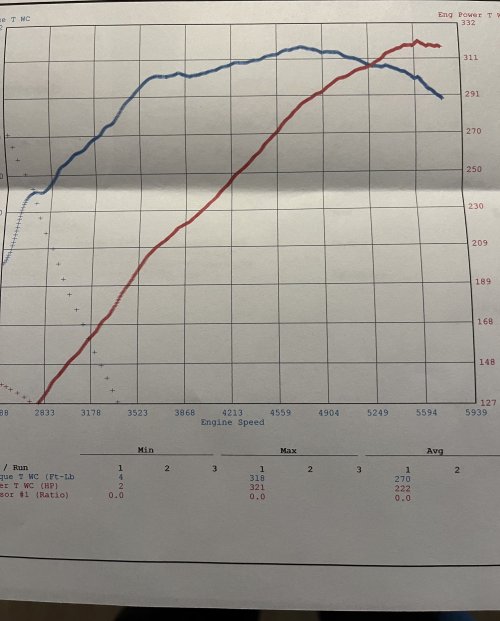

Well to everyone following , the burb just got off the Dyno. Curious to know what HP and TQ you think it made to the rear wheels.

I will post the graph later today after you get done guessing.

A stock LS2 truck engine at the crank makes 395 HP and 400 ft/lbs.

Mine has ported heads, a slightly bigger cam, and long tube headers.

On a rear wheel dyno the parasitic loss is 30-40% depending on tire size, gears, and weight.

I will post the graph later today after you get done guessing.

A stock LS2 truck engine at the crank makes 395 HP and 400 ft/lbs.

Mine has ported heads, a slightly bigger cam, and long tube headers.

On a rear wheel dyno the parasitic loss is 30-40% depending on tire size, gears, and weight.