Farmerj

Well-known member

- Joined

- Dec 12, 2021

- Messages

- 1,072

Some 15 years or so ago, I snagged a stevens 200 chambered in .30-06.

I’ve always been one to tinker with my rifles and try to get as much accuracy out of them as I don’t/ didn’t have a budget all the time for a custom built or gun shop worked over smoke pile.

The first rifles I worked over were a pair of Remington 788 rifles. One in .308 Winchester and the other a .243 Winchester. I had chose the 788 because of the action locktime history and function.

Those were the first rifles that I’d glass bedded and installed pillars and had great success with.

I never did mess with their triggers.

Prior to that, I’d had a Ruger 44 carbine refinished and while it was being hot reblued, I stripped the stock and refinished it. I sold it because of the ex-wife. Dumbest reason ever.

About that same time, I got ahold of a Turkish O/U made by Kahn. I had a guy lengthen the forcing cones, played with the action and started to polish triggers. It took my skeet average from 18 to 23-24. I spent a lot of time stripping and refinishing that stock as well.

That’s all led me to my biggest project right now which is this stevens 200 LA.

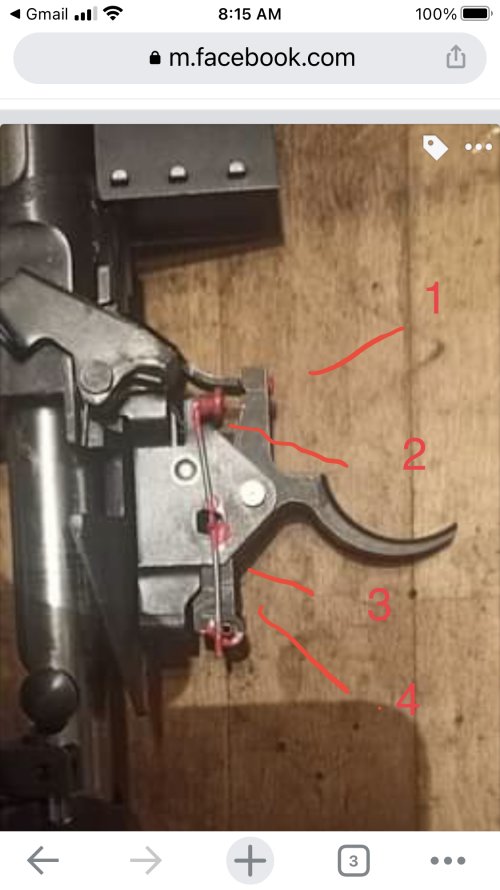

I’ve played with the trigger polishing and stoning the sear and trigger to get it to break like glass. Is it world class? Oh no. But is no where near the same lawyer class it was shipped from the manufacturer with. I’ve even started using a q-tip and Flitz to polish the pivot pins etc on the trigger assembly.

I’m happy with the trigger at the moment as the take-up, overtravel and breaking are solid and right at 2 1/2 lbs. for a hunting rifle, it might even be too light. But I can drop it from bench top height and I’ve never had it “fire” to check functionality.

I was at the range one day and a guy was shooting with a muzzle brake and got me curious. It’s made by Witt Machine &Tool out of Colorado. I’d never had a rifle with a brake before. They had a slip on version so that’s what I ordered. This rifle is like 5 1/2 lbs with the scope. So a .30-06 gives it a good kick. This brake reduces it to less than a savage model 10 I had at the time chambered in .243.

I’ve got a crappy synthetic stock this rifle came with. There’s some things I want to do with it. Fill the foreend with lead and a couple carbon arrow shafts to stiffen it up. Practice my bedding skills again. Fill the buttstock with lead and epoxy to balance it.

And that brings me to the goofy spacer on the buttpad.

I struggle with most rifles getting into a comfortable position. Tip to tip, my arm span is like 72”. And I have a long neck. Most typical rifles are a 13-13 1/2” Length Of Pull.

Boyd’s Stock has a procedure for figuring out LOP that I used when I got rid of the youth stock on that Model 10 and put a laminated stock onto. I limited it to 14” though. “Winter clothing” fitment.

But it really came back as a 15 1/4” LOP. And be since cut it back 1/2” to 14 3/4”.

The Remington 700 I got from @JLS had the bell & carlson Alaskan stock with a 13 1/4” LOP. It’s not impossible to shoot, but I also remember it’s more of a small mountain/ brush rifle.

The savage model 11 I got last year I dropped into a Bell&Carlson M40 tactical/ Varmint stock specifically because it’s got a 14 1/4” LOP.

My cousin has a Ruger rear tang mannlicher M77 in .308 Winchester.we are playing with and he was complaining he couldn’t get behind the scope comfortably. Yop, we put a block on his rifle too at 14 1/4 LOP too. I am NOT going to do Jack to modify that original rifle stock. But we may find him a Boyd’s stock he likes. He shoots it, we reload his ammo, he shoots it, we adjust the block, he shots some more.

I’m looking for a piece of hardwood, boxelder, black walnut, maple, cottonwood, cherry, hickory etc to sculpt my own stocks for my stevens project.

I want to use something like cottonwood or boxelder for the first stock so I don’t destroy a good piece of wood and can practice on.

What I hope to do someday soon for the Stevens Project.

This is just the start of a page for a project. It’s been a labor of love and interest developing the skills to take things to the next level. Things have and do distract me for a while and then I come back to it.

I have none of the shop equipment someone like @p_ham has. But I still try.

There’s times I get into a flurry and the projects I did in a manner of 6 months develop.

T-B

The Savage Model 10Y in .243 win became a .223 wylde.

Got a synthetic model 11 in .223 Remington and converted it to a .260 Remington

Acquired the Remington 700 SPS mountain clone in .280 Remington from @JLS

And I assembled the Big Horn origin I’d always wanted since the late 80’s. Included in those guns is the load development to take all those rifles to 1000 yards.

The model 10 and 11 share stocks so I can swap them in minutes. I hope to use them for NRL Hunter or PRS.

Now that I’m home daily and no longer driving semi OTR, things can begin to progress again.

But everything comes together one way or another.

I’ve always been one to tinker with my rifles and try to get as much accuracy out of them as I don’t/ didn’t have a budget all the time for a custom built or gun shop worked over smoke pile.

The first rifles I worked over were a pair of Remington 788 rifles. One in .308 Winchester and the other a .243 Winchester. I had chose the 788 because of the action locktime history and function.

Those were the first rifles that I’d glass bedded and installed pillars and had great success with.

I never did mess with their triggers.

Prior to that, I’d had a Ruger 44 carbine refinished and while it was being hot reblued, I stripped the stock and refinished it. I sold it because of the ex-wife. Dumbest reason ever.

About that same time, I got ahold of a Turkish O/U made by Kahn. I had a guy lengthen the forcing cones, played with the action and started to polish triggers. It took my skeet average from 18 to 23-24. I spent a lot of time stripping and refinishing that stock as well.

That’s all led me to my biggest project right now which is this stevens 200 LA.

I’ve played with the trigger polishing and stoning the sear and trigger to get it to break like glass. Is it world class? Oh no. But is no where near the same lawyer class it was shipped from the manufacturer with. I’ve even started using a q-tip and Flitz to polish the pivot pins etc on the trigger assembly.

I’m happy with the trigger at the moment as the take-up, overtravel and breaking are solid and right at 2 1/2 lbs. for a hunting rifle, it might even be too light. But I can drop it from bench top height and I’ve never had it “fire” to check functionality.

I was at the range one day and a guy was shooting with a muzzle brake and got me curious. It’s made by Witt Machine &Tool out of Colorado. I’d never had a rifle with a brake before. They had a slip on version so that’s what I ordered. This rifle is like 5 1/2 lbs with the scope. So a .30-06 gives it a good kick. This brake reduces it to less than a savage model 10 I had at the time chambered in .243.

I’ve got a crappy synthetic stock this rifle came with. There’s some things I want to do with it. Fill the foreend with lead and a couple carbon arrow shafts to stiffen it up. Practice my bedding skills again. Fill the buttstock with lead and epoxy to balance it.

And that brings me to the goofy spacer on the buttpad.

I struggle with most rifles getting into a comfortable position. Tip to tip, my arm span is like 72”. And I have a long neck. Most typical rifles are a 13-13 1/2” Length Of Pull.

Boyd’s Stock has a procedure for figuring out LOP that I used when I got rid of the youth stock on that Model 10 and put a laminated stock onto. I limited it to 14” though. “Winter clothing” fitment.

But it really came back as a 15 1/4” LOP. And be since cut it back 1/2” to 14 3/4”.

The Remington 700 I got from @JLS had the bell & carlson Alaskan stock with a 13 1/4” LOP. It’s not impossible to shoot, but I also remember it’s more of a small mountain/ brush rifle.

The savage model 11 I got last year I dropped into a Bell&Carlson M40 tactical/ Varmint stock specifically because it’s got a 14 1/4” LOP.

My cousin has a Ruger rear tang mannlicher M77 in .308 Winchester.we are playing with and he was complaining he couldn’t get behind the scope comfortably. Yop, we put a block on his rifle too at 14 1/4 LOP too. I am NOT going to do Jack to modify that original rifle stock. But we may find him a Boyd’s stock he likes. He shoots it, we reload his ammo, he shoots it, we adjust the block, he shots some more.

I’m looking for a piece of hardwood, boxelder, black walnut, maple, cottonwood, cherry, hickory etc to sculpt my own stocks for my stevens project.

I want to use something like cottonwood or boxelder for the first stock so I don’t destroy a good piece of wood and can practice on.

What I hope to do someday soon for the Stevens Project.

This is just the start of a page for a project. It’s been a labor of love and interest developing the skills to take things to the next level. Things have and do distract me for a while and then I come back to it.

I have none of the shop equipment someone like @p_ham has. But I still try.

There’s times I get into a flurry and the projects I did in a manner of 6 months develop.

T-B

The Savage Model 10Y in .243 win became a .223 wylde.

Got a synthetic model 11 in .223 Remington and converted it to a .260 Remington

Acquired the Remington 700 SPS mountain clone in .280 Remington from @JLS

And I assembled the Big Horn origin I’d always wanted since the late 80’s. Included in those guns is the load development to take all those rifles to 1000 yards.

The model 10 and 11 share stocks so I can swap them in minutes. I hope to use them for NRL Hunter or PRS.

Now that I’m home daily and no longer driving semi OTR, things can begin to progress again.

But everything comes together one way or another.

Last edited: