Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torque..

- Thread starter zpooch

- Start date

Walkathon

Well-known member

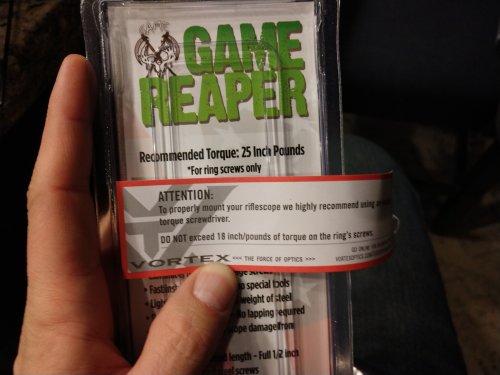

Great question. I have the same Game Reaper mounts on a couple of guns with VX2's mounted on them. I never thought to check the scope spec's for a max torque rating. I used 25 in-lbs, dry screws.

Last edited:

ShadowFast1

Active member

- Joined

- Jul 13, 2019

- Messages

- 223

I'd go with what the scope manufacturer suggests. If you exceed that and crush the tube it'll be obvious you over torqued it. They may still warranty it but they shouldn't have to.

HandgunHunter

Well-known member

I have never used a torque wrench to put on an optic. And I generally don’t use lock tight. I degrease everything and snug it down firm. I make sure the rings come down even.

Has worked for me for many years on the boomer handguns....

Has worked for me for many years on the boomer handguns....

Blacktailbc

Well-known member

Talley recommends 17-20 Inch pounds for their one piece aluminum

ShadowFast1

Active member

- Joined

- Jul 13, 2019

- Messages

- 223

Yes. 18 inch pounds is adequate to hold it in place as long as your rings are machined properly and provide enough surface area contact with the scope tube.But if the scope slides in the rings and gets damaged because I don't torque it to the rings' spec, should Vortex have to replace that?

std7mag

Well-known member

I torque mine to 18 inch pounds with the low strenth purple Loctite.

After checking ring contact area and lapping if needed.

After checking ring contact area and lapping if needed.

antelopedundee

Well-known member

I'd go with what the scope manufacturer suggests. If you exceed that and crush the tube it'll be obvious you over torqued it. They may still warranty it but they shouldn't have to.

If there is an advantage to Allen head scope screws it would be that they'd likely strip out before you could put too much torque on them, esp. if you're using them to attach scope bases. With the torx screws it's no biggie to tighten em to a snug fit without overdoing it. Overtightening with torx or slotted screws is most likely to end up twisting off the screw heads than anything else.

HuntMT16

Member

As much as I hate to admit it, I know from experience that Vortex will still warranty the scope if it is over torqued.I'd go with what the scope manufacturer suggests. If you exceed that and crush the tube it'll be obvious you over torqued it. They may still warranty it but they shouldn't have to.

ShadowFast1

Active member

- Joined

- Jul 13, 2019

- Messages

- 223

Hopefully he'll avoid that process.As much as I hate to admit it, I know from experience that Vortex will still warranty the scope if it is over torqued.

Woodrow F Call

Active member

I don't think you should do something with the attitude "If I break it, they'll replace it."

That's really a good way to ruin a good thing.

I doubt the few extra inch pounds will hurt it though. It's also possible that 18 inch pounds is plenty.

Also, torque on bolted joints usually changes between dry and lubricated. And neither specified dry or lubricated...... or with loctite.

I'd probably remove all the oil/grease, apply loctite, torque to 18 inch pounds, dab a little nail polish on the heads (as a tell tale) and see how it goes.

That's really a good way to ruin a good thing.

I doubt the few extra inch pounds will hurt it though. It's also possible that 18 inch pounds is plenty.

Also, torque on bolted joints usually changes between dry and lubricated. And neither specified dry or lubricated...... or with loctite.

I'd probably remove all the oil/grease, apply loctite, torque to 18 inch pounds, dab a little nail polish on the heads (as a tell tale) and see how it goes.

Bambistew

Well-known member

I'd hate to know what my rings are actually torqued at, but will guarantee they are well over 25 inch pounds.

I went with no loctite and 20 inch pounds. We'll see how that works

Why wouldn’t you use loctite?

I always degrease and add a drop of blue.

From the DNZ websiteWhy wouldn’t you use loctite?

I always degrease and add a drop of blue.

"Thread Locker – it is not needed with our mounts if it is installed correct. DO NOT use any type of thread locker on our long ring screws. The screws we use are longer than other companies screws. We have about 20 threads holding your scope in place on each screw. If you do use thread locker, most of the time you will have to saw or break screws to get your scope out of mount. Do not send any mount back to us for exchange or refund if it has thread locker on the mount at any spot"

I have personally experienced holding zero and tracking problems with Swarovski and Vortex scopes and determined the problem to be torquing the rings over 18 in/lbs.

Have always done bases at 25-30 in/lbs and some scopes recommend more, but Vortex recommends 15-18 in/lbs and Swarovski actually recommends 17 in/lbs max on ring screws.

Have always done bases at 25-30 in/lbs and some scopes recommend more, but Vortex recommends 15-18 in/lbs and Swarovski actually recommends 17 in/lbs max on ring screws.

antelopedundee

Well-known member

From the DNZ website

"Thread Locker – it is not needed with our mounts if it is installed correct. DO NOT use any type of thread locker on our long ring screws. The screws we use are longer than other companies screws. We have about 20 threads holding your scope in place on each screw. If you do use thread locker, most of the time you will have to saw or break screws to get your scope out of mount. Do not send any mount back to us for exchange or refund if it has thread locker on the mount at any spot"

I've never done it that I can recall, but does anyone use a torch in that situation? Also there is a product called hard as nails used to repair broken/damaged fingernails that serves the same purpose. I never use anything on the screws unless they come that way.

klampson

Well-known member

- Joined

- May 5, 2019

- Messages

- 311

I have DNZ mounts on several rifles with 30mm scopes (not Vortex). Never used Loctite with them, and I've had zero issues with the screws loosening. I torqued the ring screws to 25 inch lbs.

HandgunHunter

Well-known member

I've never done it that I can recall, but does anyone use a torch in that situation? Also there is a product called hard as nails used to repair broken/damaged fingernails that serves the same purpose. I never use anything on the screws unless they come that way.

a regular propane plumbing torch will break down red and blue lock tight with ease.

Similar threads

- Replies

- 30

- Views

- 2K

- Replies

- 54

- Views

- 3K