Good morning,

I thought I would provide you with my review and experience with the HOWA 1500 barreled action in 6.5 Creedmoor.

Early last fall Brownells had a sale on the rifle and I was able to obtain it for what I thought was a price, so I ordered the 6.5 with the threaded heavy 24” barrel.

I topped off the rifle with a EGW 20MOA rail and a Vortex HST 4-16x44 scope. I placed the rifle in a Bell and Carlson target / competition with the adjustable cheek piece:

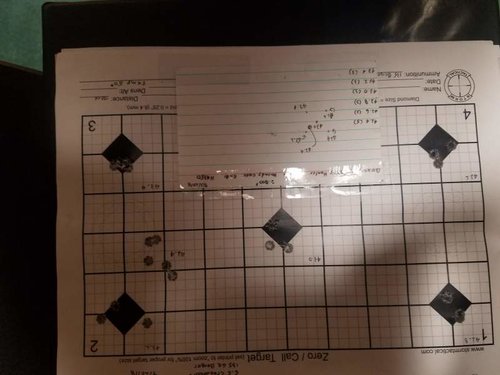

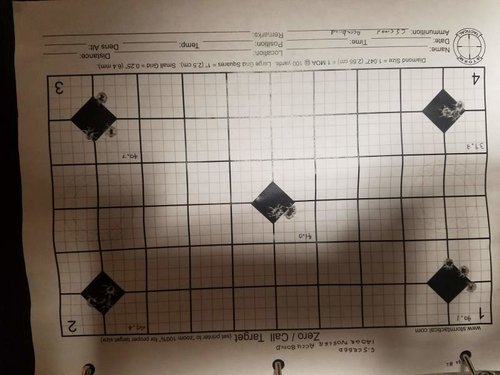

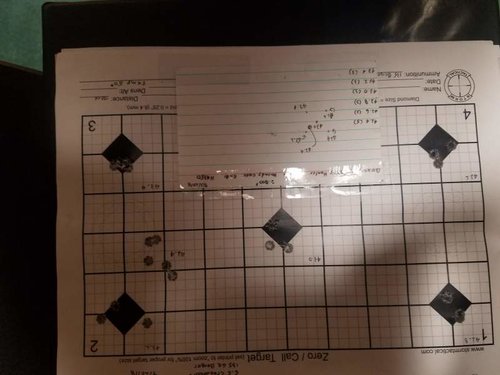

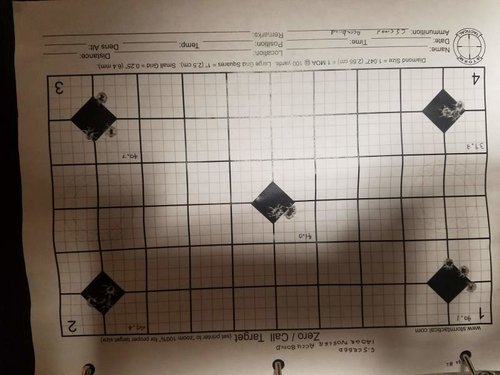

As for load work I decided to try both the 140gr Nosler Accubonds and the Berger 135gr classic hunters. Both rounds shot great and it was easy to find a load that worked for both bullets. Below are pictures of the load development at 100 yards. As you can see it didn’t take much effort to get sub MOA results.

I was pleased with the outcome and settled on a load for each bullet. In October I went to Wyoming to hunt Antelope and this is one of the rifles I brought with me. I was able to harvest an Antelope at 350 yards with the 135gr Berger. The bullet had a about a golf ball sized exit on the far side with minimal meat loss. I was very happy with the performance of the rifle and bullet.

The weather was less than ideal and it was raining and snowing all day during the hunt so the rifle was exposed to typical hunting conditions. When I got back to my tent that afternoon I noticed that the rifle was beginning to rust on t the exterior of the barrel. I was surprised by this as I had a light coat of oil on the gun and I had maintained it in the same fashion I maintain my other rifles. I have never run into this issue before and the surface rusting didn’t just wipe off. I fully disassembled the rifle, cleaned and oiled it. Here is a picture of what the barrel looked like.

I was a little irritated that the finish was not as robust as other factory finishes and I wanted the rifle to have a more durable coating so I decided to send it off to LRI in South Dakota to be Cerakoated. While the rifle was there I decided to have the barrel and bolt fluted. I elected to do the fluting as a personal preference rather than for performance reasons. Getting the file fluted and coated was more than I spent on the initial rifle. This may not be the path for everyone but it is what I wanted to do. Here is how it turned out:

I think that LRI did a great job and I would recommend them based on my interactions with them.

In summary, I am very happy with the performance of the Howa, it was very easy to find two loads to shoot sub MOA. Given that alone I would purchase another Howa. I am however disappointed in the factory finish. Possibly I got a one off and the factory finish is working well for others, that just wasn’t my experience. I have rifles from several other manufactures that have been exposed to much worse conditions and have shown little to no blemishes in the finish. If I were to do it over again I would just opt for the stainless version and call it a day. If anyone has any questions or would like me to clarify anything I would be happy to do that.

I thought I would provide you with my review and experience with the HOWA 1500 barreled action in 6.5 Creedmoor.

Early last fall Brownells had a sale on the rifle and I was able to obtain it for what I thought was a price, so I ordered the 6.5 with the threaded heavy 24” barrel.

I topped off the rifle with a EGW 20MOA rail and a Vortex HST 4-16x44 scope. I placed the rifle in a Bell and Carlson target / competition with the adjustable cheek piece:

As for load work I decided to try both the 140gr Nosler Accubonds and the Berger 135gr classic hunters. Both rounds shot great and it was easy to find a load that worked for both bullets. Below are pictures of the load development at 100 yards. As you can see it didn’t take much effort to get sub MOA results.

I was pleased with the outcome and settled on a load for each bullet. In October I went to Wyoming to hunt Antelope and this is one of the rifles I brought with me. I was able to harvest an Antelope at 350 yards with the 135gr Berger. The bullet had a about a golf ball sized exit on the far side with minimal meat loss. I was very happy with the performance of the rifle and bullet.

The weather was less than ideal and it was raining and snowing all day during the hunt so the rifle was exposed to typical hunting conditions. When I got back to my tent that afternoon I noticed that the rifle was beginning to rust on t the exterior of the barrel. I was surprised by this as I had a light coat of oil on the gun and I had maintained it in the same fashion I maintain my other rifles. I have never run into this issue before and the surface rusting didn’t just wipe off. I fully disassembled the rifle, cleaned and oiled it. Here is a picture of what the barrel looked like.

I was a little irritated that the finish was not as robust as other factory finishes and I wanted the rifle to have a more durable coating so I decided to send it off to LRI in South Dakota to be Cerakoated. While the rifle was there I decided to have the barrel and bolt fluted. I elected to do the fluting as a personal preference rather than for performance reasons. Getting the file fluted and coated was more than I spent on the initial rifle. This may not be the path for everyone but it is what I wanted to do. Here is how it turned out:

I think that LRI did a great job and I would recommend them based on my interactions with them.

In summary, I am very happy with the performance of the Howa, it was very easy to find two loads to shoot sub MOA. Given that alone I would purchase another Howa. I am however disappointed in the factory finish. Possibly I got a one off and the factory finish is working well for others, that just wasn’t my experience. I have rifles from several other manufactures that have been exposed to much worse conditions and have shown little to no blemishes in the finish. If I were to do it over again I would just opt for the stainless version and call it a day. If anyone has any questions or would like me to clarify anything I would be happy to do that.