MO Betta

Well-known member

Haven't seen a build thread here, figured I'd post one for those who might be curious of building their own black rifles. As time allows, I'll post progress pictures and explanations - depending on when I get a few tools back from a friend. Some of these steps are personal choices, especially the first couple I will post. I'm not a gunsmith, and I don't play one on TV - just someone who likes to tinker.

Dimpling barrels: Insurance on keeping set screw style gas blocks in place. Some manufacturers will send barrels pre-dimpled. This is just machining shallow holes into the barrel for the set screws to bite into.

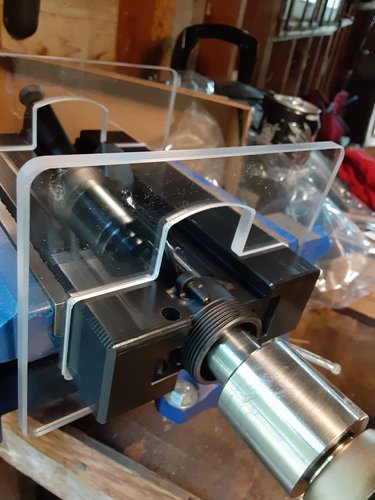

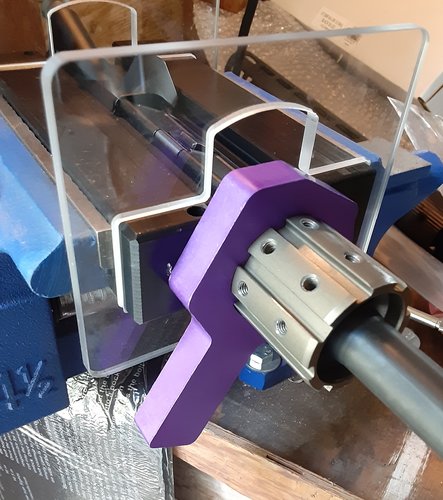

Barrel clamped into nylon soft jaw barrel vise:

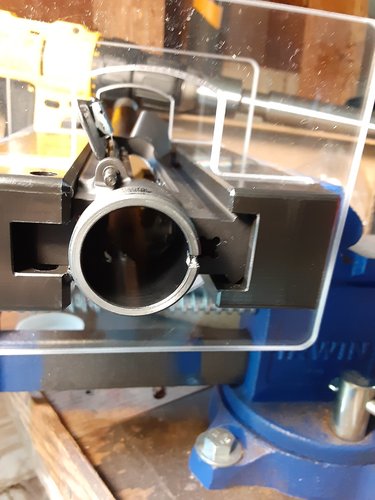

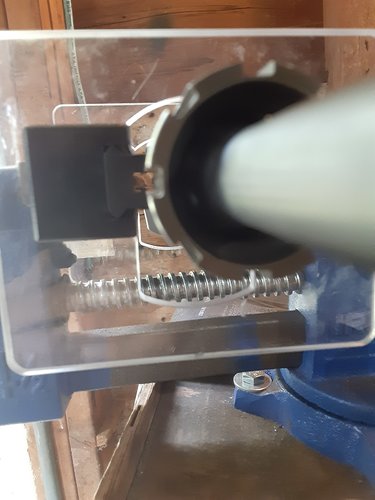

Barrel fitted with a KAK dimple jig. This jig is used to line up your dimples opposite the gas port, it is machined for certain gas block journal diameters (this one is .750) and has 5 different patterns for set screw spacing as many gas block manufacturers have different patterns. For these builds I am using Aero low profile gas blocks that have a set screw spacing of .5 inch. On one side, the jig has a pointed screw that tightens down into the gas port to align and properly space the jig, you then rotate the barrel 180° and drill.

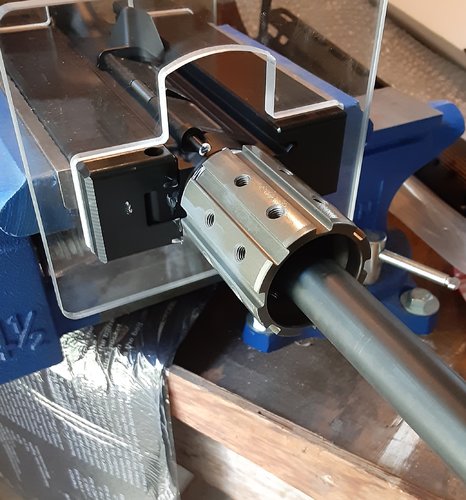

The kit comes with a bit specifically made to fit this jig, so there is no slop once inserted and a hand drill can be used. The cuts in the bit help bring the material up and out. Take your time and use cutting fluid, frequently stopping to check your work. Below is a finished barrel.

Dimpling barrels: Insurance on keeping set screw style gas blocks in place. Some manufacturers will send barrels pre-dimpled. This is just machining shallow holes into the barrel for the set screws to bite into.

Barrel clamped into nylon soft jaw barrel vise:

Barrel fitted with a KAK dimple jig. This jig is used to line up your dimples opposite the gas port, it is machined for certain gas block journal diameters (this one is .750) and has 5 different patterns for set screw spacing as many gas block manufacturers have different patterns. For these builds I am using Aero low profile gas blocks that have a set screw spacing of .5 inch. On one side, the jig has a pointed screw that tightens down into the gas port to align and properly space the jig, you then rotate the barrel 180° and drill.

The kit comes with a bit specifically made to fit this jig, so there is no slop once inserted and a hand drill can be used. The cuts in the bit help bring the material up and out. Take your time and use cutting fluid, frequently stopping to check your work. Below is a finished barrel.

Last edited: